How a Samsung washing machine works

It's not often that users think about understanding the internal workings of a Samsung washing machine, but when a malfunction occurs, this question immediately becomes a concern. To repair the machine yourself, you need to study the diagram and understand the location of its parts and components. Most washing machines have similar designs, with only a few differences. Now we'll take a closer look at Samsung washing machines specifically.

It's not often that users think about understanding the internal workings of a Samsung washing machine, but when a malfunction occurs, this question immediately becomes a concern. To repair the machine yourself, you need to study the diagram and understand the location of its parts and components. Most washing machines have similar designs, with only a few differences. Now we'll take a closer look at Samsung washing machines specifically.

What parts does it consist of?

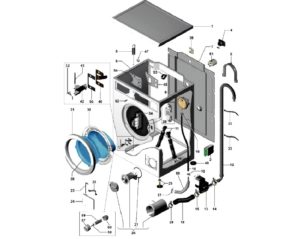

To properly diagnose problems and repair your washing machine, you need to understand its structure. Any Samsung washing machine, regardless of load type, contains the following basic components:

- electric motor;

- tank;

- pump;

- several types of pipes;

- detergent dispenser;

- various springs and shock absorbers;

- heating element (TEN);

- drain filter;

- electric pump;

- drum pulley;

- snail;

- temperature sensor;

- washing machine control module;

- special counterweights;

- hatch locking device;

- inlet solenoid valve;

- hatch door cuff;

- liquid level relay;

- power unit (is the power source for the entire device);

- drain and fill hoses;

- washing machine control panel.

The design of a washing machine consists of the basic components listed above. All elements are housed within the frame. The metal frame of the washing machine itself consists of side panels, a top, front, and rear covers, and a base. The orientation of the door—horizontal or vertical—depends on the selected loading method. To better understand the machine's structure, let's take a closer look at some of its individual components, discuss their functions, and what to do if a part fails.

Control unit

The power unit supplies power and controls all elements of the washing machine. It is the electronic module that sends a signal to turn the unit on and off through the wiring connecting the control board and each washing machine unit.

All special programs, add-ons, and washing modes are controlled and executed by this unit. Therefore, if any one element of the module fails, any part of the washing machine may stop functioning. To control basic functions, such as filling the tank with water or rotating the drum at the correct speed during spinning, the power unit contains semiconductors responsible for each function individually.

One of the components of the control module is the washing machine's control panel. By pressing buttons or turning the program selector, the user independently selects the preferred wash mode, spin speed, and water temperature. These actions transmit a signal to the power unit, which then ensures the specified conditions are met.

Important! A malfunctioning control unit is considered a serious problem and is quite difficult to fix. Therefore, it's recommended to call a qualified technician to repair the module.

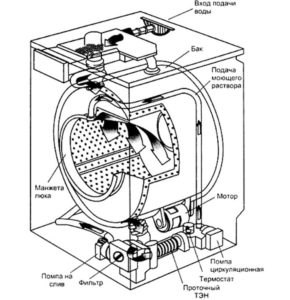

Level sensor and filling valve

The liquid level switch (also known as a pressure switch or level sensor), as the name suggests, monitors the volume of water in the tank. The pressure switch measures the pressure in the tank and sends a signal to the control unit. The electronic module, upon receiving this information, signals the fill valve to stop drawing water from the lines.

An inlet valve can have from one to three coils. These coils are where voltage is applied, allowing the valve membrane to open and begin operating. When the control unit signals the need to begin water intake, the membrane opens and begins operating. As soon as voltage is removed from the coils, it closes.

These two elements are not described together by chance; they constantly interact. The scheme is as follows: the inlet valve draws in water, and the level sensor monitors the optimal volume of liquid, preventing underfilling or overfilling.

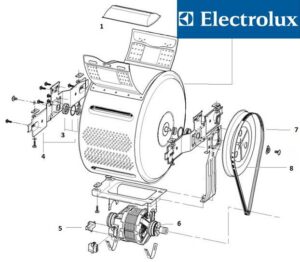

Motor and tachogenerator

This pair of components also works together. The motor "drives" the drum, and the tachogenerator ensures that the RPM matches the set value. The tachogenerator helps the control module monitor the motor RPM, as the rotation speed must be different for each wash cycle.

The washing machine's electric motor ensures the drum rotates correctly at a set speed. Most modern Samsung washing machines are equipped with inverter motors. In this case, the motor is mounted directly to the drum, resulting in greater efficiency and power. This design is reliable and durable; inverter motor failure is extremely rare.

The commutator motor drives the drum using a special belt. This causes wear on the electric brushes, so the motor will need to be repaired from time to time.

Heating element and temperature sensor

The heating element's function is to heat the water in the drum to the desired temperature. Each wash mode requires a specific temperature, so the control unit, upon receiving the user's selected program, transmits the set temperature to the heater.

The temperature sensor monitors the temperature and, once the set temperature is reached, transmits a signal to the power unit. The thermostat is presented in the form of a metal tube installed directly in the housing of the heating element. Having received a signal from the temperature sensor, the main unit automatically switches off the heating element.

Springs, shock absorbers and counterweights

These components prevent the washing machine from wobbling or bouncing during operation. This is crucial, as otherwise the machine would simply destroy itself from the inside during the spin cycle. What parts are we talking about?

- Shock absorbers secure the bottom of the drum to the washing machine body and prevent it from bouncing during spinning and hitting the walls.

- The springs support the reservoir from above, their function is very similar to the purpose of shock absorbers.

- Counterweights are weighted blocks that are connected to the outer surface of the tank and serve to maintain balance.

During machine operation, counterweights can be damaged by strong vibration. However, in most cases, their mountings simply become slightly loose; tightening them can resolve the rattling issue.

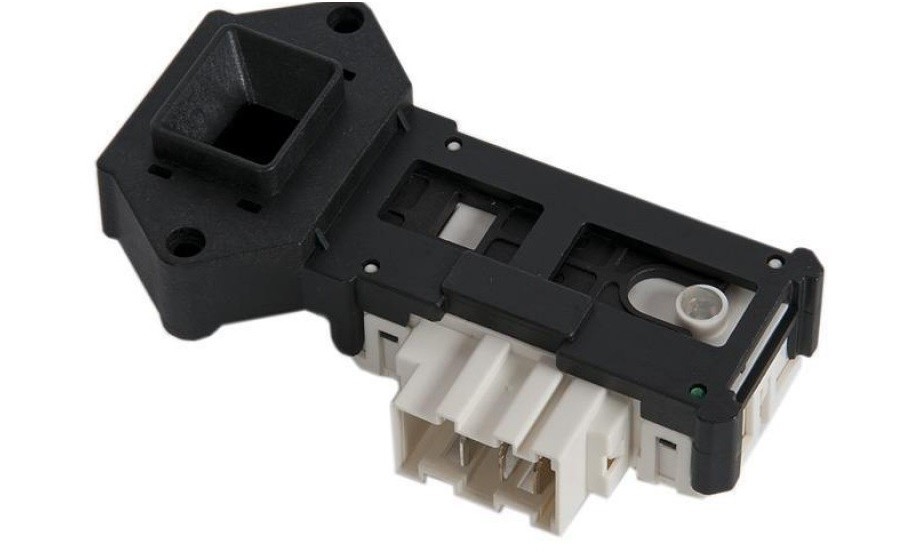

Locking device and cuff

The door lock is nothing more than an electronic lock that closes the door before the wash cycle begins. By closing the door, the user activates only the mechanical lock, and after the program starts, a click is heard—this is the electronic door lock engaged. Only after this signal does water begin to fill the drum. The door lock prevents accidental opening during washing.

The seal is used to ensure the door is closed more securely. It is a rubber seal that prevents water from leaking through the gap between the washing machine body and the door. It is important to keep the seal clean, dry, and undamaged. If the seal breaks, do not use the machine until the problem is fixed, as liquid from the drum will spill onto the floor.

Snail, filter, pump

A pump is a special device used to remove wastewater from the drum after the pre-wash, main wash, or rinse cycle. Samsung washing machines come with two types of pumps:

- synchronous;

- asynchronous.

The pump's internal components are standard: a motor and an impeller. A volute is attached to the top of the pump, to which the inlet and drain hose are connected. In most cases, pump failure occurs due to foreign objects entering the system.

If coins, wrappers, small toys, and other items are left in the pockets of clothes loaded into the drum, they can end up in the drain pipe. This can clog not only the filter and hoses, but also the pump itself. The debris filter is located in a volute that attaches to the pump. As you can see, these three elements are closely interconnected.

Plastic tank and metal drum

The plastic tank is a crucial part of the washing machine; it collects water and mixes it with detergent. It's important to ensure that the tank remains completely sealed. Otherwise, water leaks can occur, which can be difficult to fix.

The drum is made of metal and is located inside the tub. Housewives load their laundry into it. As you may have noticed, the drum's surface is ribbed, which ensures better cleaning of soiled fabrics. The drum is also equipped with plastic combs (ribs), which allow the laundry to be spread out inside, ensuring that the mixture of water and detergent penetrates into the items.

Different Samsung washing machine models have drums with different volumes and, accordingly, different maximum laundry loads.

Hoses, pipes and powder receiver

The detergent dispenser is designed to store laundry detergent and fabric softener before they are dispensed into the tank. The intelligent compartment prevents different types of detergent from being dispensed simultaneously. At the beginning of the wash cycle, the dispenser dispenses laundry detergent and fabric softener during the rinse phase.

The drain and inlet hoses are essential components of the unit. They are necessary for the timely intake of water into the tank and the drainage of waste water. Besides the hoses, it's worth mentioning the pipes, which are located inside the housing and serve to transport water throughout the system.

A washing machine's design is quite complex, and at first glance, it may seem impossible to understand the layout and operation of each individual part. However, if you thoroughly research the subject and fully understand it, you can certainly figure it out.

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment