How does a Hansa washing machine work?

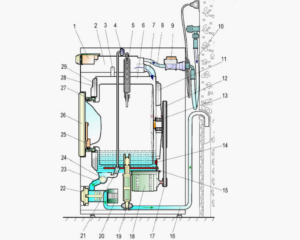

The design of all front-loading machines is similar. Naturally, there will be differences, such as an additional hatch for reloading, a commutator motor or inverter, and the display or lack thereof, but the basic configuration is the same. The operating principle of automatic washing machines is also identical.

The design of all front-loading machines is similar. Naturally, there will be differences, such as an additional hatch for reloading, a commutator motor or inverter, and the display or lack thereof, but the basic configuration is the same. The operating principle of automatic washing machines is also identical.

It's best for users to understand the structure of their Hansa washing machine. Knowing where each part is located and what they do helps them spot problems early and troubleshoot them quickly. Therefore, we'll describe the structure of a typical washing machine and explain the locations of the machine's main components.

Parts and components hidden in the body

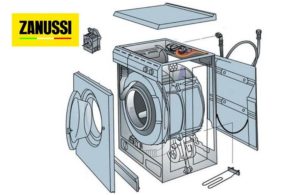

Knowing how your washing machine works and understanding how it operates allows you to repair it yourself without paying extra for service. Most problems can be easily fixed without any special skills, simply by understanding the insides of your washing machine. Every Hansa front-loading machine includes:

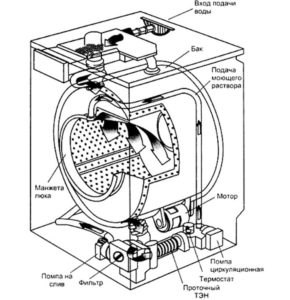

- metal body;

- counterweights;

- shock absorbers;

- metal strip (located under the top “cover”);

- tank-drum unit;

- drum door;

- sealing cuff, it is fixed by two rings: an inner and an outer clamp;

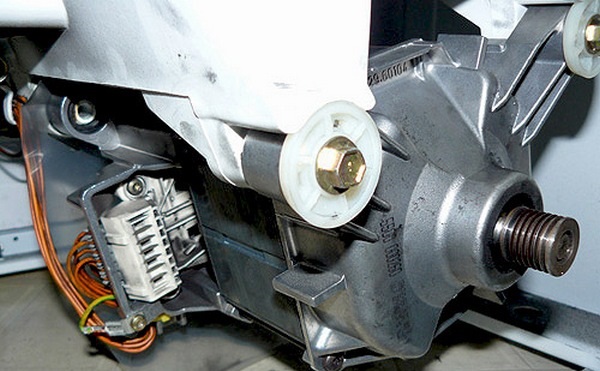

- engine. It can be either a brushed or an inverter motor;

- Drive mechanism. Only found on collector washing machines;

- control panel with programmer and buttons;

- drain pump for pumping water out of the system;

- trash filter;

- Heating element and thermostat;

- main control module;

- water level sensor;

- filling solenoid valve;

- UBL;

- inlet hose and drain "sleeve";

- bearings and seal;

- powder receptacle;

- drain pipe.

Wiring ensures communication between each washing machine unit and the main control module.

In addition to the components listed above, any front-loading washing machine also contains rubber gaskets, fasteners and clamps, latches, terminals, small tubes, and connectors. To properly understand the operation of a Hansa washing machine, it's important to understand the functions of each component and how the machine will behave if a particular part fails.

How do the machine's elements interact?

The normal operation of an automated machine will be impossible if even one sensor, even the smallest one, fails. It's important for every element of the system to perform its intended functions. The main control module controls the operation of all units and components of the Hansa washing machine. The electronic unit is responsible for alternating the cycle stages, controlling when to fill and drain the system, controlling the drum rotation speed, and more. The module ensures communication between the internal components of the washing machine.

The largest component of a Hansa automatic washing machine is the tank. In the Polish brand's washing machines, it is made of plastic. The tank is held in place within the machine's housing by shock-absorbing elements: springs and dampers. The plastic container houses the drum, which is made of stainless steel. A motor drives the centrifuge.

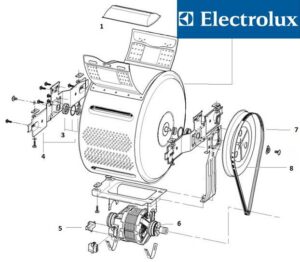

The design of washing machines with a commutator motor differs slightly from that of machines with an inverter. The former have a drive belt stretched between the drum pulley and the electric motor. The belt, receiving impulses from the motor, spins the centrifuge. The high rotation speed of the drum ensures a thorough cleaning of the laundry.

It's also important to understand how any washing program starts. What the user sees: the machine is plugged in, the dashboard lights up, the desired mode is selected, and the cycle is activated. What happens inside the machine: the "brain" receives signals from the control panel and understands the selected cleaning parameters. The control module opens the inlet valve, and water begins to fill the drum. When necessary, the unit stops filling the machine, activates the heating element, and so on until the spin cycle and draining begin.

Using the buttons on the control panel, the user can adjust certain washing programs, change the spin speed, and add options such as a double rinse. The "intelligence" system processes the commands and ensures that the cycle is performed strictly according to the specified parameters.

Washing tanks

The largest component of a front-loading washer is the tank. Hansa machines have a plastic tank, which helps keep the cost down. The tank sits level within the machine; it's rare to find models with a tilted tank. A stainless steel drum is built into the tank. Water from the house's water supply first fills the tank and then flows through holes in the spinner's surface to the laundry. In addition to the holes, the drum walls are equipped with plastic combs, which ensure a more thorough cleaning of fabrics.

This is a fairly reliable knot. The tank, and especially the metal drum, is damaged very rarely. The only problem is that the plastic drum can be punctured by a foreign object dropped inside. To prevent damage to the drum, carefully check the pockets of items before loading them into the machine. Any paper clip, bobby pin, or nail can "squeeze" through the hole in the drum surface and puncture the plastic.

Furthermore, the unit is damaged if the maximum load weight is systematically exceeded. For example, you can't pack 7 kg of laundry into a 5 kg machine. Such a load will quickly cause the machine to malfunction.

How does the machine heat water?

All Hansa washing machines are connected to cold water. They are equipped with a special heating element, a tubular element, responsible for heating the water. This element is located directly under the washing machine's drum. Accessing it is easy: simply remove the top of the machine, the back panel, and the drive belt.

It is important to descale the machine periodically to extend the life of the heating element.

If you don't follow expert recommendations and treat scale, your heating element will have to be replaced every few years. This is because the heating element is constantly exposed to hard water. Heavy impurities settle on the element, forming limescale. When this layer becomes thick enough, it impairs the heating element's thermal conductivity and causes it to burn out.

Experts also advise against running multiple high-temperature cycles in a row. This stress isn't good for the heating element. It's recommended to let the machine cool down before running another "hot" wash. The heating elements in Hansa models consume 1800 watts, which is the average power consumption of any other heating element.

Electric motor

The washing machine drum is driven by a motor. The electric motor spins the centrifuge to the user-set RPM via a drive belt. All models Hansa equipped with collector motors. Inverters are superior in quality to commutators, but direct-drive motors are also significantly more expensive. The service life of an inverter motor is 10-15 years, while a commutator motor still requires periodic maintenance.

The collector motor is sensitive to voltage fluctuations in the network, so it is better to use a stabilizer when connecting Hansa washing machines.

The commutators will need to be serviced every 3-5 years. This applies to the brushes, which are prone to wear. When the graphite rod wears down by more than 50%, the pair must be replaced. This work can be done at home, without calling a professional.

The electric motor is the "heart" of an automatic washing machine. It starts working immediately after the wash cycle is initiated. The control module regulates the motor speed, thereby controlling the drum rotation speed from low, at the beginning of the cycle, to maximum, during the spin phase.

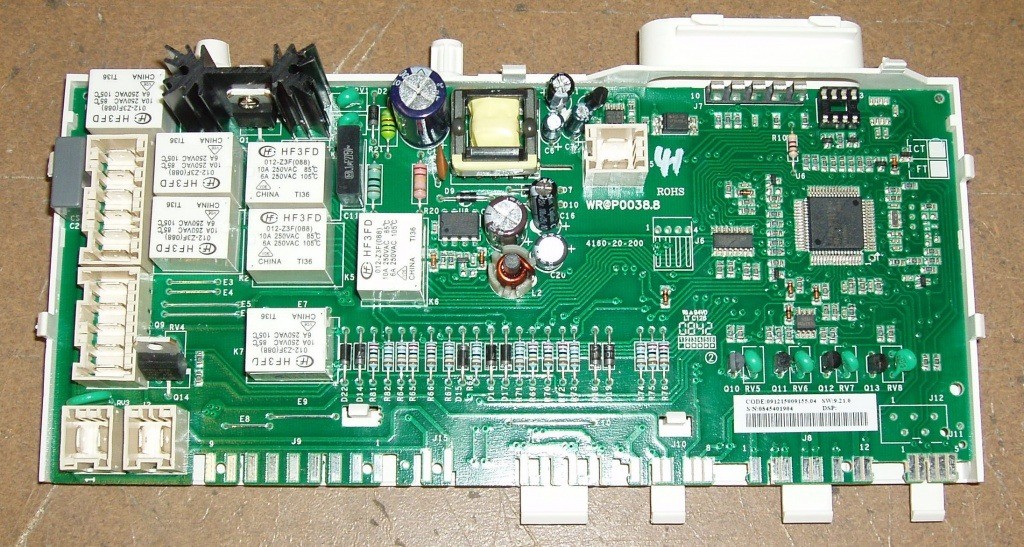

Control board

As mentioned earlier, the main control module is the "brain" of an automatic washing machine. It connects all the system's components, monitors their functions, and ensures the washing machine's smooth operation.

The user "communicates" with the module via the control panel. By pressing buttons on the dashboard, the user can inform the "brain" of their preferences for the upcoming wash. The board receives all the necessary information about the selected program, enabled additional options, the desired spin speed, and the water temperature. The electronic unit consists of many semiconductor elements and tracks, each of which is responsible for a specific component of the machine.

The control board contains triacs, thyristors, triggers, capacitors, a controller and other semiconductors.

Some elements of the control module are responsible for filling the tank with water by controlling the inlet valve. Others monitor the pressure switch. Still others accelerate and decelerate the motor to the required speed, and so on. Modern Hansa washing machines can automatically detect system malfunctions and notify the user. For example, if any of the control board sections detects a malfunction, the machine displays a corresponding error code on the display. By referring to the displayed error, the owner can more easily narrow down the possible problems and troubleshoot them.

So, there's nothing magical about the design of front-loading washing machines. By carefully studying the instructions, you can understand the components of the machine and what each part does. And with additional knowledge regarding the disassembly procedure, you can repair the equipment yourself without overpaying a technician.

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment