How does a top-loading washing machine work?

The desire to understand the workings of a top-loading washing machine arises when a malfunction or breakdown occurs. By understanding the components and sensors, you can check the machine yourself and fix the problem, saving a tidy sum. The task is generally simple – most top-loading machines are similar in design and controls. The main thing is to find the time and proceed consistently.

The desire to understand the workings of a top-loading washing machine arises when a malfunction or breakdown occurs. By understanding the components and sensors, you can check the machine yourself and fix the problem, saving a tidy sum. The task is generally simple – most top-loading machines are similar in design and controls. The main thing is to find the time and proceed consistently.

Components of the "vertical"

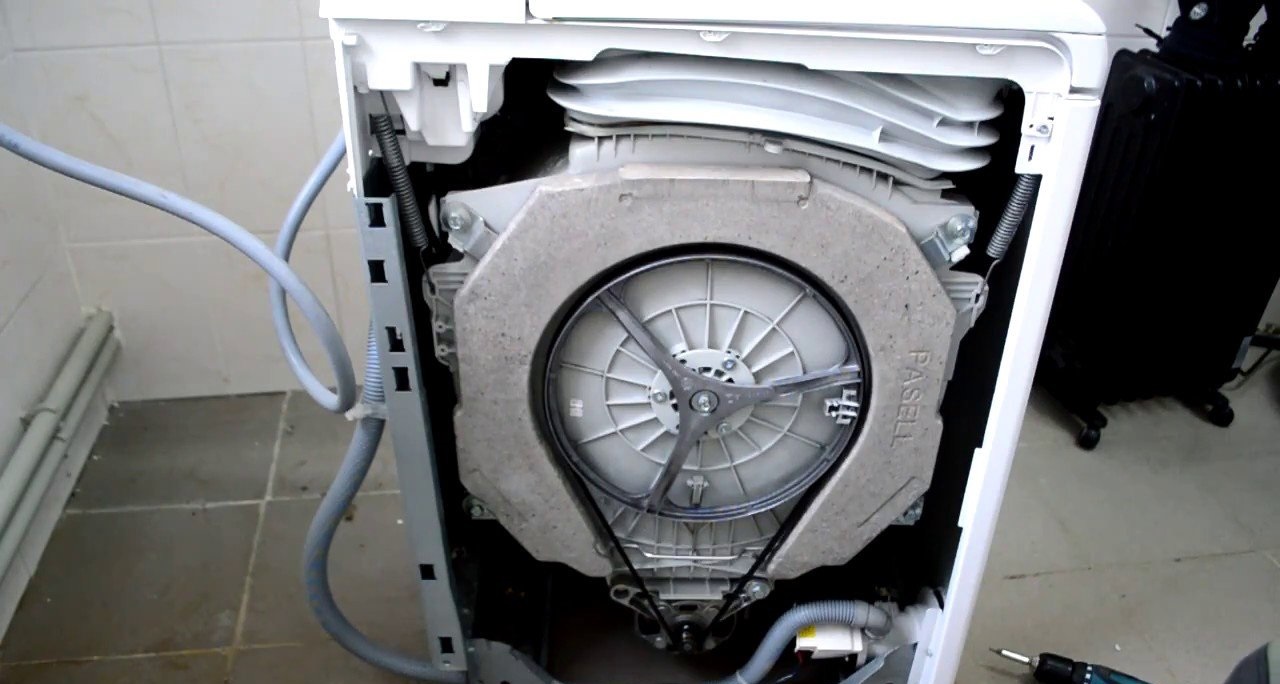

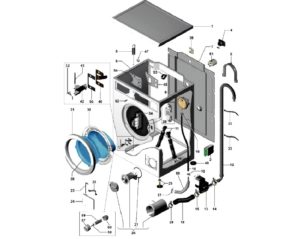

To get to know your washing machine, you need to know all of its components. Only by studying the names and purposes of the main components can one grasp the relationship between the structural elements and their location. So, each “vertical” necessarily has the following details:

- electric motor;

- washing tank;

- metal drum with folding doors;

- drainage pump;

- rubber pipes and hoses;

- drum pulley;

- drive belt (if the washing machine does not have a direct drive);

- powder and gel tray (also called powder receptacle and dispenser);

- shock absorption system (springs, vibration dampers);

In vertical washing machines, items are loaded through the top lid!

- tubular electric heater (TEN);

- drainage filter;

- control board (control module);

- dashboard;

- snail;

- thermistor;

- counterweights;

- electronic lock (UBL);

- inlet valve;

- cuff;

- pressure switch (water level sensor).

All the washing machine components are "hidden" within the metal casing. The dashboard and access panel are located on top, while the sides are covered with blind panels. A drip tray is often attached to the bottom of the machine.

To check the machine and troubleshoot a problem, names alone aren't enough—you need to know the structure, operating principle, and the location of the parts. Let's take a closer look at the components.

Machine control center

Most modern washing machines are equipped with electronic controls. Unlike "old" mechanical ones, everything is controlled and regulated by a module—a connecting unit consisting of sensors, conductors, tracks, and microchips. The system works as follows:

- the user sets the cycle settings by pressing buttons or rotating the programmer on the dashboard;

- the control board records the selected parameters and sends a command to execute the program;

- the required system nodes are turned on;

- the wash starts.

The control module is what starts the washing machine: it processes information from the dashboard and transmits commands "up the chain" to its destination. Turning on the appliance, filling with water, starting the motor, and draining the water—all of this is performed only after "permission" from the electronic unit, which uses a multitude of triacs, sensors, and contacts. The board then monitors the operation, monitoring the signals and data coming from the nodes. In the event of a failure or deviation, the device detects the malfunction and urgently terminates the cycle.

It is not recommended to test and solder the board at home – its testing and firmware installation should be performed by specialists!

If the electronic system malfunctions, the machine stops working: it won't turn on, doesn't respond to user commands, or freezes. Finding the problem is difficult, as either an individual track or the entire control unit could be faulty. In any case, the board loses control of the washing machine and, for safety reasons, prevents it from starting.

An electronic module is an extremely complex component. Understanding its structure and operation on your own is quite difficult, especially for those unfamiliar with electrical engineering. It's best to play it safe and contact a service center immediately if you suspect a faulty board.

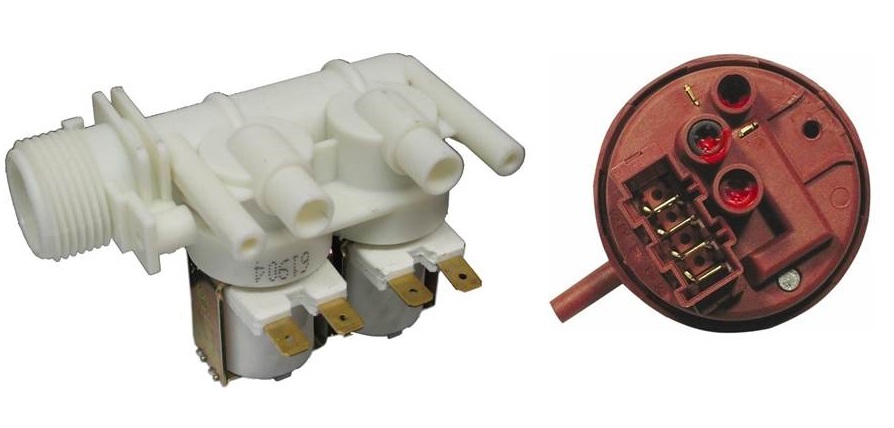

Parts responsible for clean water

The filling system in a top-loading washing machine consists of a pressure switch, hoses, and an inlet valve. Water intake begins immediately after the user starts the program by pressing the "Start" button on the control panel. The drum fills as follows:

- the board receives a signal about the need to fill;

- pressure switch – a water level sensor that measures the pressure in the tank and signals the level of filling;

- the module makes sure that there is no water in the tank and sends a command to the valve to fill;

- voltage is applied to the inlet valve, its membrane is activated, and the flap rises;

- water from the water pipe flows through the inlet hose into the machine;

The pressure switch has a long tube that goes down into the tank and measures the pressure in it.

- The pressure switch controls the volume of water;

- when the required volume is reached, the pressure switch signals the unit;

- the module cuts off the current supply;

- the valve membrane closes;

- recruitment is closed.

All elements of the filling system constantly interact, and the main "controller" is the water level sensor. It ensures the tank fills to a predetermined level, preventing underfilling or overfilling.

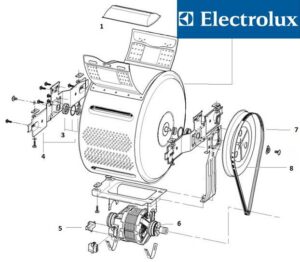

The "heart" of the machine

The "heart" of a washing machine is its engine. It's the electric motor that accelerates the drum shaft, ensuring the cylinder rotates at the desired speed. The speed is controlled by a tachogenerator, which is attached to the engine and constantly monitors the speed, eliminating chaotic rotation and abrupt changes in direction.

An electric motor provides the driving force. Modern vertical rollers are equipped with inverter motors that are connected directly to the drum shaft, eliminating the need for a drive belt. This system eliminates the need for intermediaries, making cylinder rotation more efficient, reliable, and safer.

Some top-loading washing machines feature commutator motors. Here, the motor's impulse is transmitted to the drum via a drive belt wrapped around pulleys. This option is cheaper but less reliable: the belt often comes off, breaking or stretching. Another drawback is the brushes, which wear against the motor housing during operation and need to be replaced periodically.

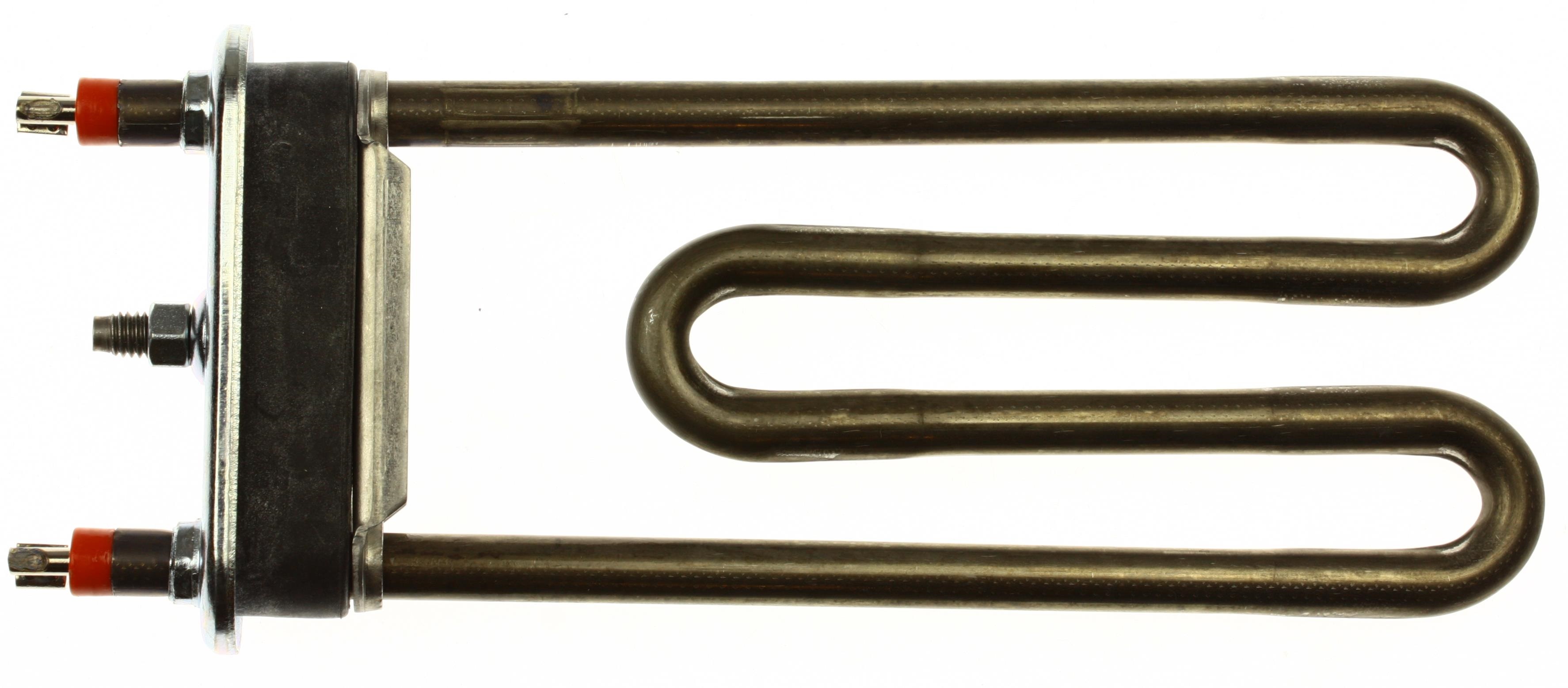

Where does the hot water come from?

As with front-loading machines, vertical machines use a tubular electric heater (TEH) for heating. Once the user selects a mode and adjusts the temperature, the electronic board receives the parameters and activates the heater. The heater receives a signal, and once the filling is complete, its "coil," located in the tank, begins to heat up.

To avoid overheating the heating element, do not run three high-temperature cycles in a row!

The heating level is monitored by a thermistor, a temperature sensor. It looks like a metal tube and is located in the heating element itself. When the set temperature is reached, the device signals the module, which shuts off the heater.

Weights and shock absorption system

When the drum spins, centrifugal force inevitably occurs, which is absorbed by shock absorbers. They compensate for the outgoing vibration, preventing the washing machine from bouncing around the room or hitting the wall. The following components ensure the washing machine's stability:

- dampers – vibration dampers-stands with a built-in spring, connecting the washing tank to the machine body;

- springs - the tank is suspended on them from above and on the sides;

- Counterweights are concrete blocks that are attached to the bottom or sides of the vertical structure, making the entire structure heavier.

The shock absorber system bears the brunt of the shock. Constant vibration causes the dampers to wear out, the springs to stretch, and the counterweights to become loose. This is especially true if the washing machine is improperly installed or used for too long. In such cases, it's necessary to tighten the mounting bolts and replace the worn components.

Lock and seal

Each vertical washer has both a mechanical and an electronic lock. The mechanical lock is activated by the normal door closing, when the locking tongue engages the corresponding groove. The electronic lock is activated automatically when the washing program starts, thanks to the locking device (UBL). This prevents the user from opening the drum once the cycle has begun.

The drum's seal is also maintained by a hatch cuff—a rubber seal stretched over the edges of the cylinder. It closes the gap between the tank and the housing, preventing leaks and clogging. If the rubber is damaged, do not start the wash cycle, as water will start to leak out.

Electric pump

Draining is a mandatory step in any washing machine. To empty the tank, the machine is equipped with pipes, hoses, a pump, and a drain filter. The key element of the drainage system is the pump, which pumps the waste liquid from the drum into the sewer.

The vertical pumps are equipped with two types of pumps:

- synchronous;

- asynchronous.

Each pump is designed identically. It is powered by a motor, which accelerates and spins an impeller—a propeller that directs the water along the desired trajectory. The pump is mounted on a volute, and a drainage hose and fittings are connected to it to drain the liquid.

The waste filter protects the washing machine from clogging – most of the waste and dirt settles on its coil!

Problems with water drainage are rare, and not caused by the pumps. The main cause of obstructed drainage is clogged hoses caused by debris that has gotten into the washing machine. The drain filter is the most vulnerable, as it collects dirt and foreign objects. To prevent this, inspect the filter pockets and periodically clean the nozzle and all components of the drainage system.

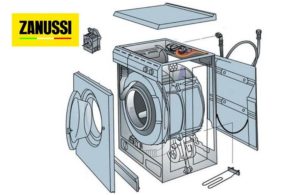

Main reservoirs

The key component of a washing machine is the tank—a sealed plastic container. Tap water is mixed with the detergent. On upright machines, the tank faces upward, while on front-loading machines, it faces forward.

The drum is made of stainless steel. Clothes are loaded into the cylinder, and a motor spins it to a set speed. It's smaller, has perforated walls, and fins—plastic paddles that "mix" the clothes and foam the powder.

The drum volume varies from 3.5 to 15 kg and depends on the capacity of the machine.

Hoses and powder box

A washing machine's essential component is the detergent drawer. This is a plastic tray used for adding detergent.Powder or gel is taken from the bins in measured doses – at specified intervals and at specific stages of the program. The main thing is to fill the concentrate correctly, choosing the appropriate compartment of the dispenser.

Each powder compartment has 3-4 compartments – for main and pre-wash, bleach and conditioner.

We mustn't forget about the system of pipes that carry water from the water supply to the drum and then to the sewer. They "connect" the machine's components, reminiscent of human blood vessels. The inlet and drain hoses are especially noteworthy. The former fills the machine, while the latter drains it from the tank.

Automatic washing machines are multifunctional appliances, incorporating dozens of components, sensors, and pipes. However, if you're willing to understand their design and mechanics, you can do so without any special training.

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment