How does a Whirlpool washing machine work?

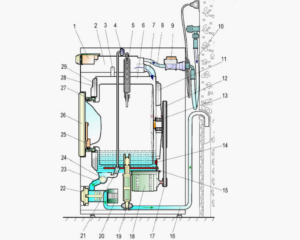

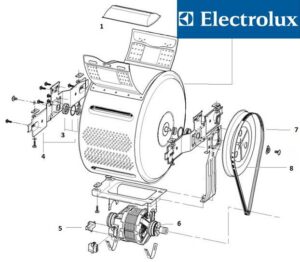

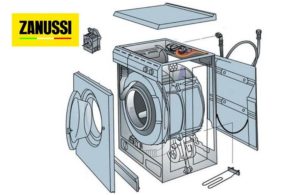

The design of all front-loading washing machines is virtually identical. Of course, there are differences, such as an additional door for adding laundry, more or less advanced firmware for the presence or absence of a drive belt, or display, but the basic configuration is identical. The operating principle of the front-loading units and components remains unchanged. The design of a Whirlpool washing machine is quite simple, and using this brand's appliances as an example, it's easy to understand the basic components of all washing machines. Let's take a look at the structure of a typical washing machine.

The design of all front-loading washing machines is virtually identical. Of course, there are differences, such as an additional door for adding laundry, more or less advanced firmware for the presence or absence of a drive belt, or display, but the basic configuration is identical. The operating principle of the front-loading units and components remains unchanged. The design of a Whirlpool washing machine is quite simple, and using this brand's appliances as an example, it's easy to understand the basic components of all washing machines. Let's take a look at the structure of a typical washing machine.

List of structural elements

It's important for users to know how their washing machine works. If the machine suddenly breaks down, understanding how it works and its components will allow you to diagnose and fix the problem yourself.

There's nothing complicated about washing machines. Any front-loading washing machine has:

- frame;

- counterweights;

- fastening metal strip;

- shock absorbing elements: springs and dampers;

- tank with drum;

- hatch door;

- cuff with internal and external fixing clamp;

- engine (unlike the model, it can be inverter or collector);

- drive mechanism (for machines equipped with a “collector”);

- dashboard;

- pump;

- trash filter;

- heating element;

- temperature sensor;

- control module;

- pressure switch;

- inlet valve;

- hatch locking device;

- inlet and outlet hose;

- tank-drain pump hose;

- bearing unit;

- Detergent dispenser.

The insides of the washing machine are connected to each other by wires and pipes.

The machine also contains sealing rubbers, various fasteners, terminals, and connectors. These are the key components that ensure the proper functioning of the Whirlpool washing machine. Let's look at each part and describe how it works.

Well-coordinated work of parts

Uninterrupted operation of the equipment can only be ensured if all components properly perform their assigned functions. The main control module issues commands to the internal components, which also controls the entire washing process. The electronic unit sets the sequence of cycle stages and ensures interaction between the main units and components.

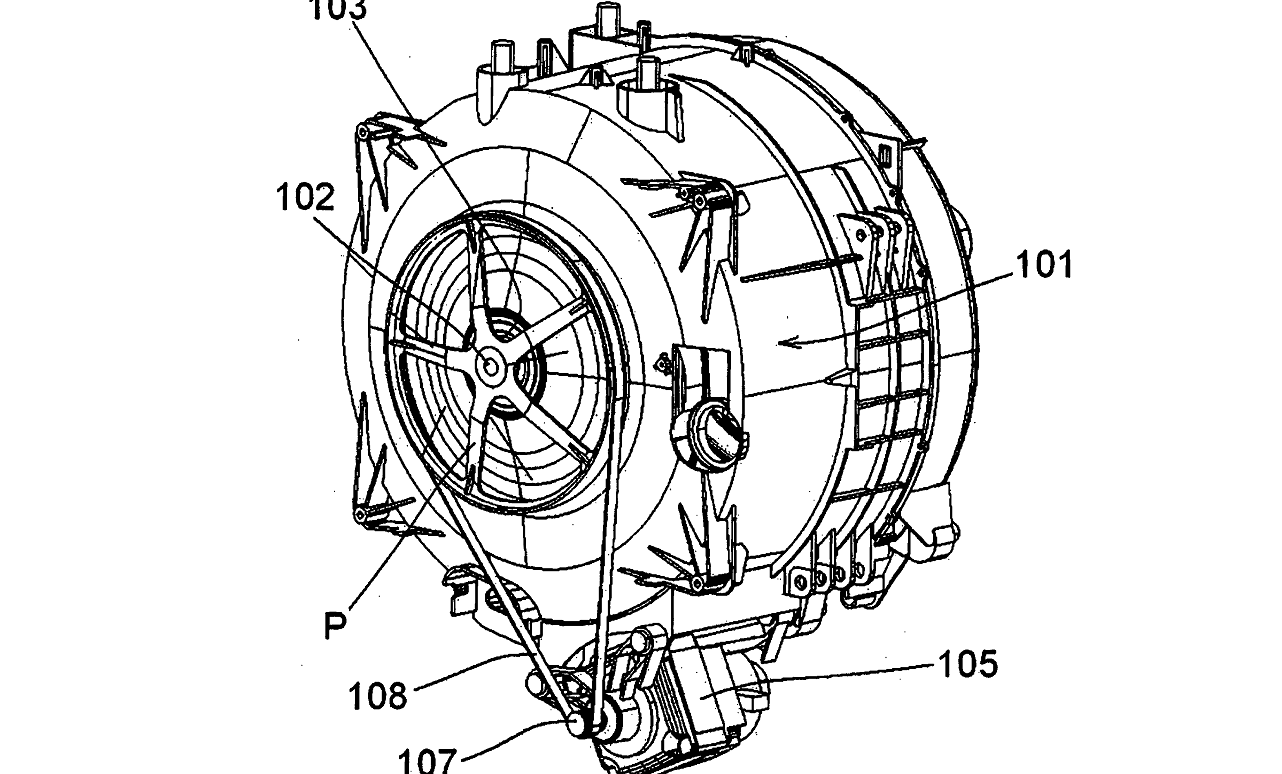

The most impressive component of a Whirlpool washing machine is the drum. In this brand's models, it's made of plastic. More expensive machines are equipped with a stainless steel tank. The tank is supported within the housing by springs and dampers. The drum, a stainless steel container with a porous surface, is housed within the drum. This is where the dirty laundry is placed to be washed. An electric motor, powered by a drive mechanism, spins the centrifuge.

The drive belt is attached to the small motor pulley and the large drum "wheel." The rubber band receives impulses from the motor and spins the drum. The high rotation speed is what cleans the laundry.

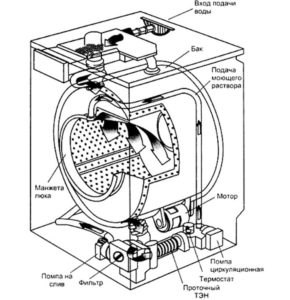

It's important to understand what happens after the user starts the desired cleaning program. The machine's "brain" opens the inlet valve, and water begins to flow into the system. At the same time, the pressure switch monitors the filling level of the machine and, when the desired level is reached, sends a signal to the module. The electronic unit then signals the machine to stop filling.

Next, the control board activates the heating element, which heats the water to the preset temperature. The "brain" then controls the wash cycle, and finally commands the drain pump to pump water out of the system and the motor to accelerate the drum to maximum speed for the spin cycle.

Every wash cycle is performed this way. Depending on the user's selected program, additional steps may be added, such as soaking or double rinsing.

This is only a general overview of how a washing machine works. For a more detailed examination, it's worth examining each machine component and its functions individually.

Laundry containers

The largest container in a washing machine is the tub. In Whirlpool washing machines, the tub is made of plastic, which helps keep the price down. Some brands offer stainless steel tubs, which are more durable and reliable, but the final cost of these models is significantly higher. The tub sits level in the front-loading models; it's rare to find a model with a tilted tub.

The tank contains a metal drum with a porous surface. Water is poured into the tank through pipes, where it mixes with detergent, and then flows through holes to the laundry. In addition to the holes, the drum walls are equipped with plastic combs, which ensure more thorough cleaning of fabrics.

Damage to the drum assembly is extremely rare. These are very reliable components of a Whirlpool washing machine. Failure to follow basic safety precautions can lead to serious consequences.

For example, a paper clip, pin, or hairpin left in a pocket can get stuck between the drum and tub and puncture the plastic. A dropped bra underwire can have the same effect. Therefore, it's crucial to inspect items before loading them into the machine, and wash potentially hazardous items in special bags. The unit can also be damaged if the maximum load capacity is not met. Systematically cramming 8 kilograms of laundry into a 6 kg machine is not a good idea.

Where does the hot water come from?

Most washing machines are connected to a cold water supply. A heating element is responsible for heating the water in automatic machines. The tubular element is located under the tank. To access it, you need to remove the housing cover and the back panel, and remove the drive belt.

The heating element is considered a rather vulnerable part of the Whirlpool washing machine.

If the user neglects the recommendation to periodically clean the inside of the machine, the heating element will need to be replaced quite frequently. The heating element is constantly in contact with water, which contains heavy impurities. As a result, scale builds up on its surface. This layer of limescale impairs the element's thermal conductivity, leading to overheating.

Manufacturers recommend using high-temperature washing as little as possible, especially avoiding multiple consecutive cycles with water heated to 60-90°C. It's advisable to allow the machine to cool before using it again. The heating elements in Whirlpool washing machines have a power rating of 1800-2200 W. This value is comparable to the power consumption of any other heating element.

The "heart" of the machine

The drum in which the clothes are washed is spun by a motor. The motor, via a drive mechanism, accelerates the "centrifuge" to the desired speed. Automatic machines Whirlpools are equipped with commutator electric motors.

Collectors are cheaper than inverter motors, but they are less reliable. Inverters have a significantly longer service life without repair, are less sensitive to voltage fluctuations, and require no periodic maintenance. However, they are significantly more expensive.

Collector motors are quite sensitive to surges in the power grid, so it is advisable to connect them through a stabilizer.

Another drawback of collectors is the need for periodic maintenance, specifically replacement of the brushes. After approximately 3-5 years of use, the carbon rods wear down and need to be reinstalled. Replacing the brushes is easy—you can do the job yourself at home.

The motor is considered the "heart" of the washing machine. It starts working immediately after the desired washing program is launched. Depending on the user-activated mode, the control module monitors the electric motor's speed, constantly slowing it down or accelerating it to its maximum.

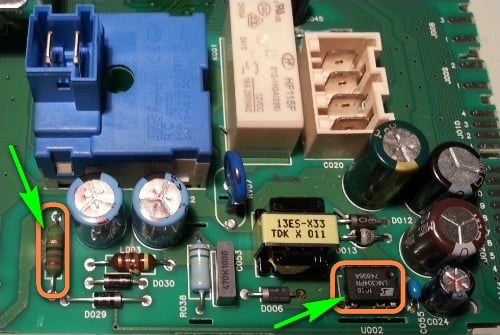

The "brain" of the washing machine

The main control module controls the washing machine's operation. The user, via the control panel, communicates all their preferences regarding the upcoming wash cycle to the "brain": the desired mode, additional options, the desired heating temperature, whether a spin cycle is required, etc.

The control board of the Whirlpool washing machine consists of semiconductor elements: triacs, triggers, resistors, capacitors, thyristors, and a controller.

Each component of the automatic washing machine is controlled by its own section of the circuit board. Some semiconductors regulate the drainage system, others monitor the inlet valves, and still others control the motor.

Thus, upon detecting a fault in any part of the circuit or a communication failure, the automatic washing machine notifies the user by displaying an error code on the display. Washing machines without a display indicate a malfunction by flashing a light on the control panel. Self-diagnostics make it easier for the owner to identify the cause of equipment malfunctions. It is the washing machine's "intelligence" that determines the sequence of each washing program. All acceptable algorithms are "programmed" into the firmware. The user only needs to inform the module which mode is required via the control panel.

There's nothing super-complex about the design of front-loading machines. Knowing where everything is located and which parts perform which functions allows you to independently diagnose the equipment and perform minor repairs without overpaying technicians.

Interesting:

1 reader comment

Headings

Washing machine repair

For buyers

For users

Dishwasher

What is the marking of the thyristor, which is installed under the designation TC2?