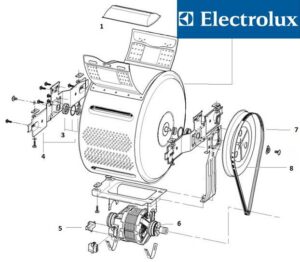

How an Electrolux top-loading washing machine works

When household appliances are working properly, users don't even bother to understand how a particular device works. People usually only wonder about the "structure" of their washing machine when a malfunction occurs. Knowing the components, their locations, and how they interact allows you to diagnose the problem yourself without calling a technician.

When household appliances are working properly, users don't even bother to understand how a particular device works. People usually only wonder about the "structure" of their washing machine when a malfunction occurs. Knowing the components, their locations, and how they interact allows you to diagnose the problem yourself without calling a technician.

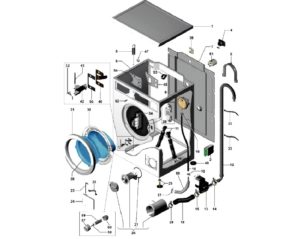

So, let's take a detailed look at the design of an Electrolux top-loading washing machine. Understanding the components of this "home helper" will make it easier to find and fix the cause of a malfunction. We'll explain which parts of the top-loading machine perform what functions.

What parts is the car made of?

Electrolux upright washing machines have a similar design. There may be some differences, for example, if a particular model is equipped with a steam generator, but these are usually minor. The equipment manual describes the design of the washing machine and also provides a diagram of the location of the main components and parts of the washing machine. Therefore, it is recommended to start by studying the user manual.

Any Electrolux vertical washing machine includes:

- electric motor;

- tachometer;

- control module;

- tank;

- metal drum with doors for loading/unloading laundry;

- drain pump;

- snail;

- rubber pipes and hoses;

- drive belt;

- detergent dispenser;

- shock-absorbing elements (springs and struts – vibration dampers);

- heating element;

- drain filter;

- dashboard;

- concrete weights;

- thermistor;

- drum cuff;

- lid locking device;

- water inlet valve;

- pressure switch.

Almost all of the above components are hidden inside the metal body of the vertical washer. The control panel with a rotary dial and buttons is located on the lid of the washing machine. A drip tray is located underneath the machine.

To diagnose a washing machine, it is important to understand how the main parts of the washing machine work and where they are located.

Therefore, we'll examine in detail the purpose and operating principle of each part of the Electrolux vertical freezer. We'll describe where each element is located, what it consists of, and how to test it for functionality.

Control board

The "brain" of the washing machine is the electronic module. The control board controls all other parts of the washing machine. If it fails, the operation of the vertical machine stops completely.

Electronically controlled automatic machines operate as follows:

- The user selects a washing program using the selector, and then adjusts the algorithm settings using the buttons on the control panel;

- the electronic module receives commands and starts the mode with the specified settings;

- the necessary components of the washing machine begin to work;

- The control unit monitors the process, introducing new units into operation and disabling unnecessary ones as the cycle progresses.

The control board initiates the washing machine's operation. Only after receiving a signal from the module does the inlet valve open and begin to let water through, the motor generates pulses and spins the drum, and the pressure switch measures the liquid level in the drum. Every action of the washing machine is controlled by the "brain" of the washing machine.

The control board contains numerous semiconductors and circuits. Each element is responsible for the operation of a specific component of the washing machine. If the electronic module detects the slightest deviation from the norm, it urgently interrupts the cycle and notifies the user of the malfunction. An error code corresponding to the malfunction appears on the display.

One of the most frustrating and costly breakdowns of an Electrolux vertical washing machine is damage to the electronic module. This type of malfunction can cause unpredictable behavior. If the control unit fails, the machine may:

- do not respond to user requests;

- hang at any stage of the cycle;

- do not turn on;

- Do not start filling or draining water, etc.

In such a situation, finding the cause can be very difficult, as such "symptoms" can occur not only with a damaged control unit. Therefore, if the machine isn't filling with water, you'll need to check the inlet hose, the inlet valve, the pressure switch, and only then the electronic module. If the drum isn't spinning, inspect the drive belt, motor, pulley, and finally the circuit board.

If you don't have any experience with electronics, it's best not to even attempt to repair the control module yourself, as this can cause further damage.

This is one of the Electrolux washing machine malfunctions where repair at home is practically impossible. In this case, it's best to seek professional help. Proper diagnostics are impossible without knowledge and experience, and repairing the circuit board usually requires professional equipment and modern software.

Elements of the filling system

Every washing machine cycle begins with water filling the drum. At this point, the fill valve and pressure switch are activated. Immediately after the user presses the "Start" button, the machine begins operation. Here's how the drum fills:

- the control module receives a signal about the need to collect water;

- The pressure switch measures the pressure in the system and transmits information to the “brain”;

- the electronic unit receives information about the empty tank and gives the command to fill the tank with liquid;

- the system sends an impulse to the filler valve, its membrane is triggered, opening the flap;

- water starts to flow into the machine through the inlet hose;

- The pressure switch controls the water level in the tank;

- when there is enough water, the sensor informs the control module;

- the machine's "brain" stops supplying voltage to the electromagnetic valve;

- The inlet valve membrane drops, the damper closes, and the fluid flow stops.

All components of the filling system work in perfect harmony. A pressure switch monitors the tank's fullness, preventing overfilling or underfilling. A "brain" coordinates the operation of the components, receiving and transmitting signals.

What problems might arise at this stage? The inlet filter on Electrolux vertical washers often becomes clogged. This prevents the machine from filling, or fills very slowly, causing the module to display an error. The filter needs to be cleaned every six months.

The intake valve itself may also fail. This part cannot be repaired and must be replaced. Sometimes the pressure switch stops working, in which case you'll need to either clean the pressure line or install a new level sensor.

Electric motor

The engine is the "heart" of any automatic washing machine. The motor starts the drum, spinning it. A tachogenerator, mounted on the electric motor, controls the rotation speed. Without a tachogenerator, the cylinder would spin erratically, without controlling either the direction of rotation or the RPM.

Some modern Electrolux top-loading washing machines are equipped with inverter motors.

In inverter washing machines, the motor is directly connected to the drum shaft. This connection is safer and much more efficient. In brushed washing machines, the motor's impulses are transmitted to the drum wheel via a drive belt, which acts as an "intermediary."

Inverter machines are more expensive. Belt-driven designs are much cheaper, but also less reliable because:

- the drive belt has the property of stretching, breaking and falling off the pulley;

- collector motors contain electric brushes that wear out over time and require replacement;

- Collector machines consume more electricity during operation.

The electric motor of Electrolux vertical washers doesn't fail very often. The only problem is that the commutator brushes wear out over time, so they need to be replaced after 3-4 years of use. Sometimes the motor winding breaks, but this is a very rare problem. The motor's functionality is tested with a multimeter.

Electric heating element

The heating element is responsible for heating the water to the set temperature. The user simply selects the program and washing temperature, and the control module receives this information and transmits it to the heating element. The heating element, in turn, gets to work.

A thermostat works in conjunction with the heating element. This sensor monitors the water temperature. Once the desired temperature is reached, the thermistor transmits information to the control module, which turns off the heater.

The temperature sensor is installed near the heater. The thermistor is a small metal tube. The thermostat and the heating element are connected by wires.

Electrolux users often encounter heating elements that burn out. If hard water is not softened and the machine is not descaled, scale builds up on the heating element first. This impairs the element's thermal conductivity, causing it to fail.

It's also not recommended to run more than two high-temperature modes in a row. This will put maximum strain on the heating element. If the tubular heater isn't allowed to cool before the next cycle, it may burn out.

What are the concrete pieces and springs inside for?

When the drum rotates, centrifugal force is generated, and special elements are provided in the washing machine to dampen it. Shock absorbers reduce outgoing vibration, and counterweights ensure the stability of the device. If it weren't for these parts, the washing machine's body would wobble in all directions, and the "home helper" would definitely jump around the room.

The stability of Electrolux vertical washing machines is ensured by:

- Vibration dampers, or shock absorbers. They are equipped with a built-in spring that connects the drum to the washing machine body;

- springs. They secure the washing machine tank from above and from the sides;

- Counterweights. Blocks are located in several places; they add weight to the frame, keeping the machine in place.

Over time, shock absorbers, constantly exposed to external forces, wear out. Dampers become damaged, springs stretch, counterweights become loose, and sometimes even deform. Checking the condition of the shock absorbers is easy: press firmly on the tank and lower it. It should immediately return to its original position without bouncing up and down.

Assessing the condition of the counterweights is even easier. Remove the washing machine cover and side panels. This will give you access to the concrete blocks, which can be easily inspected.

The shock absorber system will wear out faster if the washing machine is installed incorrectly or not level. It's important to adjust the machine's body from the start to ensure it's level.

You can replace worn shock absorber components yourself. To do this, you need to purchase new components, partially disassemble the vertical suspension body, and install the new dampers in place of the damaged ones.

Hatch cuff and lock

Each vertical washer has both a mechanical and an electric lock. The mechanical lock engages when the lid is closed, with the tongue engaging the groove. When the cycle starts, the machine is additionally locked by an electronic device.

It is the UBL that prevents the lid of the Electrolux washing machine from being opened during washing.

The door lock will lock the panel until the end of the cycle. Only when the machine has finished will the electronic lock be released. Then, the lid can be opened.

A rubber seal ensures the drum of a vertical washing machine is tightly sealed. The seal is located along the edges of the cylinder. It completely covers the gap between the tank and the body, thereby preventing leaks.

If the rubber seal becomes deformed, water will begin to leak from the washing machine. Do not use the machine in this case. The seal must be replaced immediately, as the system must always be leak-proof.

A "motor" that removes impurities

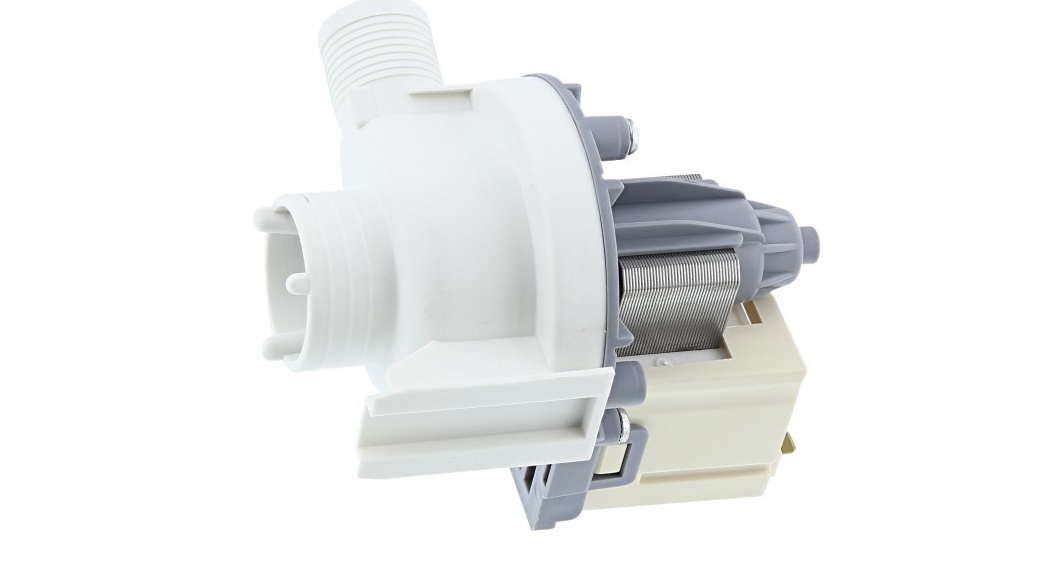

A crucial step is draining the waste water from the drum. The machine drains several times during the cycle. For example, after soaking, during the main wash, and before rinsing. The drainage system includes several components:

- pump;

- hoses and pipes;

- trash filter;

- drainage sleeve.

A drain pump pumps water from the tank into the sewer. Electrolux washing machines come with two types of pumps:

- synchronous;

- asynchronous.

Regardless of the type, the pumps operate on the same principle. They are activated by a small motor that spins an impeller. The pump is mounted on a volute. Drain pipes are connected to it to transfer water from the tank to the sewer.

A debris filter is located at the bottom of the vertical washing machine's drum. It collects lint, threads, hair, and foreign objects left in pockets, preventing clogging of the drain pipe and pump. Be sure to clean the filter element periodically – approximately once every 2-3 months.

Drainage problems in Electrolux vertical washers are most often caused by blockages. Dirt clogs the debris filter, pipes, drain hose, and pump impeller. Therefore, it's important to clean your washing machine regularly. Pump failures are rare.

Tank and drum

The tub is the largest component of the washing machine. Water and detergent are mixed in the plastic container, and the soap solution then flows into the drum. In upright washing machines, the tub faces upward, while in front-loading machines, it faces forward.

Electrolux vertical washing machines have a drum that can hold from 4 to 8 kg of laundry, depending on the washing machine model.

While the tub of Electrolux vertical washers is made of plastic, the drum is made of stainless steel. This material is not damaged by constant contact with water. To prevent unpleasant odors from developing, it's a good idea to regularly ventilate the washing machine by leaving the lid slightly ajar.

The drum surface is perforated. Water flows from the tank through these holes. The metal drum also contains plastic paddles. These paddles are used to agitate the laundry and foam the detergent.

Powder box and hoses

Every vertical washing machine also has a detergent dispenser. It's located under the lid of the washing machine. Electrolux detergent dispensers typically have three compartments:

- for pre-wash (marked with the Roman numeral I);

- for main wash (symbol II);

- for conditioner-rinse (the compartment is marked with a picture of a flower).

It's important not to confuse the compartments, as detergent is drawn from each compartment at a specific point in the cycle. It's completely incorrect to wash items with fabric softener and then rinse with water and detergent. This will require restarting the wash cycle.

Water, pouring through the inlet valve, goes directly into the detergent drawer, and only then, through the pipes, into the tank and drum. Inside the machine is a whole system of hoses through which liquid circulates. They can be compared to the blood vessels in the human body.

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment