How a Whirlpool top-loading washing machine works

Under normal circumstances, users don't need to understand how their washing machine or other household appliances work. Knowing how a Whirlpool top-loading washing machine works is usually helpful when the equipment malfunctions and requires repair. If the owner of a "home helper" is familiar with the system, they can first check the main components and sensors themselves and then fix the problem without calling a service technician. Whirlpool machines are generally similar, so this manual will cover most modern models.

Under normal circumstances, users don't need to understand how their washing machine or other household appliances work. Knowing how a Whirlpool top-loading washing machine works is usually helpful when the equipment malfunctions and requires repair. If the owner of a "home helper" is familiar with the system, they can first check the main components and sensors themselves and then fix the problem without calling a service technician. Whirlpool machines are generally similar, so this manual will cover most modern models.

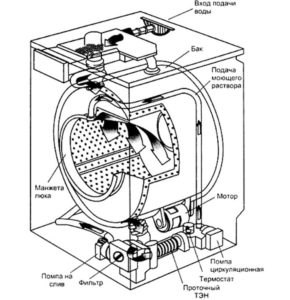

What's inside the machine body?

When getting to know a top-loading washing machine, you need to know the list of components. By studying it, the user will be able to understand the relationship of key nodes and their approximate location. So, in every top-loading washing machine you can find a lot of parts.

- Electric motor.

- Tank.

- Metal drum with sliding doors.

- Drainage pump.

- Branch pipes with rubber hoses.

- Drum pulley.

- Drive belt.

The last element can be found in non-direct drive devices.

- Compartment for household chemicals, also known as a powder receptacle.

- A shock absorption system consisting of springs and vibration damping struts.

- Heating element for heating water.

- Drainage filter.

- Washing machine control module.

- Control Panel.

- Snail.

- Thermistor.

- Counterweights.

- Hatch locking device.

- Inlet valve.

- Rubber cuff.

- Water level sensor, also known as pressure switch.

Almost all of the components listed are located inside the metal housing. The dashboard and hatch cover are mounted on top of the unit, while blind panels can be seen on the sides. A drip tray is usually found underneath the machine.

It's impossible to check the functionality of a washing machine's key components without understanding how they work and where they are installed. Therefore, we'll examine the system in detail in the following sections of this article.

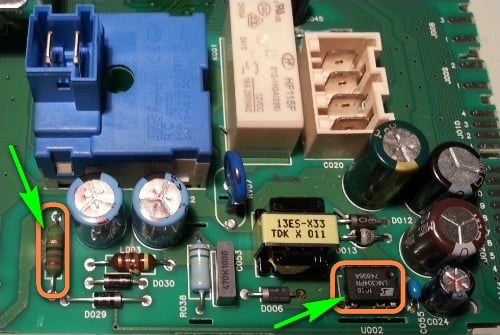

Electronic filling

The most important thing in any modern washing machine is the control board, which controls the operation of all processes. While in older devices the system's functionality depended on mechanics, in new devices everything is regulated by a control module. How do electronically controlled household appliances work?

- The housewife selects the working cycle, as well as its features, using the selector and keys on the control panel.

- The control module accepts input data and runs the program with the selected settings.

- The necessary key components of the washing machine are activated.

- The cycle begins.

The control board activates the "home assistant," as it receives and transmits information from the control panel to the system's key components. Activating the appliance, filling with water, starting the electric motor, draining waste liquid—each of these actions begins only after a command from the washing machine's "brain."

An electronic unit consisting of sensors, contacts, and triacs then monitors the equipment's operation, tracking all possible information from other components. If the control module detects a malfunction or the slightest deviation, it will urgently stop the operating cycle and notify the user by displaying the appropriate error code.

Never attempt to repair the control board yourself, as without experience, professional equipment, and modern software, you could accidentally damage the part even further.

One of the most frustrating washing machine breakdowns is related to damage to the electronic unit. If the control module fails, the entire machine will not function properly – it will either stop turning on or freeze during operation and become unresponsive. Finding the source of the problem in this situation is very difficult, as failures can occur not only if the entire module is critically damaged, but also if individual components, such as the tracks, fail.

In any case, regardless of the nature of the damage to the circuit board, it loses control of the washing machine, so as a precaution, it prevents the system from starting. This problem is rarely resolvable on your own, so it's best to call a technician immediately for a thorough diagnosis and subsequent repairs.

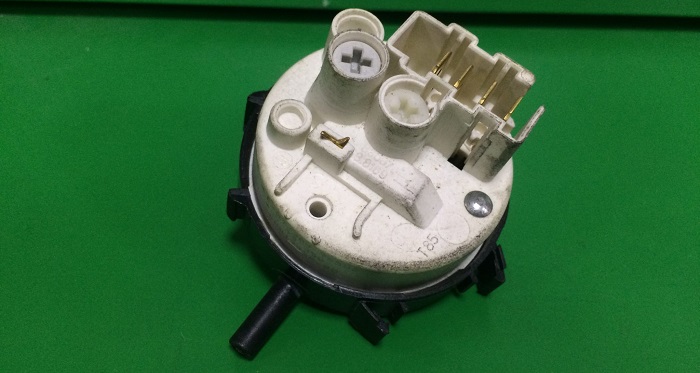

Main valve and sensor

Now let's turn our attention to another crucial system—the filling system. It includes a pressure switch, hoses, and an inlet valve. Water collection for the working cycle usually begins immediately after the housewife initiates the start of the wash by pressing the “Start/Pause” button. How exactly is the drum filled?

- The control module receives a signal that it needs to fill with water for washing.

- The water level sensor measures the pressure in the tank and transmits information about the current water level.

- The board receives information about the empty tank and transmits a command to fill the tank with liquid.

- The system supplies voltage to the inlet valve, which triggers the membrane and opens the damper.

- Water from the water supply system begins to flow into the tank through the inlet hose.

- Next, the water level sensor measures the current pressure using a long tube lowered into the tank.

- It is this part that controls the water volume – as soon as the required water level is reached, the pressure switch will transmit a corresponding signal to the control module.

- The washing machine's "brain" will stop the voltage on the inlet valve.

- The inlet valve membrane will close again and water will stop flowing into the system.

Thus, each element of the filling system works as a coordinated team, monitored by the pressure switch. Thanks to the water level sensor, the tank always fills to the required level, preventing underfilling and overfilling.

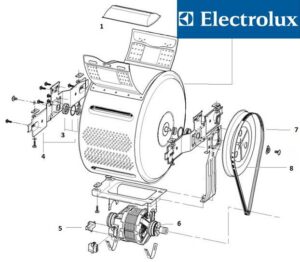

What makes the drum spin?

If the electronic board is the "brain" of the system, the "heart" is the electric motor. The motor drives the drum shaft, which rotates the cylinder at the required RPM. A tachogenerator attached to the motor controls the RPM. Without this small component, the cylinder would rotate erratically and could abruptly change direction.

The electric motor acts as the driving force in the system. New top-loading washing machines are equipped with inverter motors, directly connected to the drum shaft without a drive belt. This connection is much more reliable, safer, and more efficient, as there are no "middlemen" in the unit.

However, modern vertical-loading equipment sometimes uses commutator motors. In this case, the motor's impulse is transmitted to the drum via a drive belt wrapped around pulleys. This design is much cheaper, but also less reliable, as the belt often slips off the pulleys, breaks, and deforms over time. It's also important to remember about the brushes, as they gradually wear against the motor housing during use, so they need to be carefully monitored and replaced if they wear out.

What heats up cold water?

Just like in front-loading machines, in top-loading machines the water is heated by a tubular electric heater. The housewife only needs to select the program and heating temperature; the control module will then receive this data and transmit it to the heating element. The heater will receive a signal and, after filling with water, will begin heating the liquid.

It is not recommended to use the washing machine three times in a row, choosing cycles with high water heating, as this may cause the heating element to burn out.

In addition to the water heater, a thermistor—a special temperature sensor that monitors the temperature of the liquid in the system—is also used. This component looks like a small metal tube located within the tubular electric heater itself. Once the water temperature reaches the required level, the thermistor notifies the control board, which stops the heater.

Why shock absorbers and concrete blocks?

Owners of washing machines have probably noticed that their equipment vibrates heavily during the spin cycle. The vibration could have been even stronger if the shock absorbers inside the housing had not dampened the centrifugal force that occurs when the drum spins excessively. Shock absorbers dampen outgoing vibration, preventing the washing machine from bouncing during operation and damaging floors, walls, and surrounding objects. What exactly ensures the stability of a Whirlpool washing machine?

- Dampers are vibration dampers with a built-in spring that connects the washing tank and the washing machine body.

- Springs on which the tank is suspended not only from above, but also from the sides.

- Counterweights, which look like concrete blocks attached to the bottom or side of the appliance, add weight to the appliance, keeping it in place.

Ultimately, the shock absorber system absorbs all the increased vibration, causing it to fail over time instead of other key system components that otherwise couldn't handle the load. Constant vibration loosens the concrete counterweights, stretches the spring, and wears out the dampers.

This happens even faster if the washing machine was installed improperly or is nearing the end of its lifespan. If this is the case, you need to properly position the appliance, level it with a spirit level, tighten the mounting bolts, and replace any old shock absorber components that have become deformed or worn out over time.

Elastic band and locking mechanism

Every top-loading washing machine has not only a mechanical but also an electric locking mechanism. The mechanical part is activated during normal door closing, when the locking tongue engages the groove. The electrical part of the system is activated automatically as soon as the user initiates a cycle. This is achieved through a door locking device—the door locking device prevents the door from being opened during a wash cycle, which would cause water to drain out of the drum through the door.

As for the drum's watertightness, it's ensured by a rubber seal located around all edges of the cylinder. This rubber seal tightly seals the gap between the drum and the washing machine body, completely blocking water leaks. Therefore, if the rubber seal is damaged, don't even attempt to start the machine, otherwise liquid will leak through the deformed areas of the rubber seal, causing severe water damage to your flooring.

What pumps dirty water out of the machine's tank?

Any washing machine should drain the used liquid after successful operation. For this purpose, it is equipped with pipes, hoses, a pump, and a drainage filter. The most important component of this system is the pump, as it allows water to drain from the system into the sewer. Modern pumps come in two types:

- synchronous;

- asynchronous.

Regardless of the type, pumps are designed in the same way. They are activated by a small electric motor, which, as it accelerates, spins an impeller, which directs the water along the desired path. The pump is mounted on a volute, and a drainage hose and fittings are connected to it to direct the water into the drain.

Be sure to keep an eye on the dust filter – it protects your household appliances from becoming clogged with debris.

Drainage system failures are rare, especially due to pump damage. Most often, users experience drainage problems due to clogged hoses and the drain filter, which regularly accumulates dirt and foreign objects. Therefore, it's important to periodically clean the entire drainage system and remember to remove small items such as coins, buttons, and paper clips from pockets.

The largest unit of the machine

The drum is an extremely important part of the washing machine. This sealed plastic container mixes water from the mains with detergent and then redirects it into the drum. In top-loading washing machines, the drum is installed with the opening facing upward, while in front-loading systems, it faces forward.

The drum can hold from 3.5 to 15 kilograms of laundry, depending on the specific model of the “home assistant”.

The drum itself is made of stainless steel to prevent deformation during heavy use due to constant contact with water. The laundry is first loaded into the drum, and then it spins to the required speed using an electric motor. The drum itself is smaller than the tub, with perforated walls and plastic fins—special paddles that agitate the laundry and foam the detergent during operation.

Dispenser and hoses

Finally, any washing is impossible without a special detergent, for which the machine has a powder receptacle. This plastic dispenser is usually divided into several segments - for pre-wash and main wash, as well as for conditioner and bleach. All chemicals are removed from the compartments at the appropriate time, depending on the current stage of the work cycle. Therefore, it's crucial to add each product to the correct compartment of the tray.

You also need to consider the system of pipes that first transport water from the water supply into the drum and then out the drain, which is somewhat similar to the blood vessels in the human body. Finally, we should mention the inlet and drain hoses, which are necessary for bringing water into the appliance and pumping it out of the tank.

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment