How to remove the drum from the washing machine

You may need to remove the drum from the washing machine's tub when replacing bearings, seals, or spiders. In any case, removing the drum requires almost complete disassembly of the machine. We'll show you how to do it yourself, quickly and without making mistakes.

You may need to remove the drum from the washing machine's tub when replacing bearings, seals, or spiders. In any case, removing the drum requires almost complete disassembly of the machine. We'll show you how to do it yourself, quickly and without making mistakes.

Tools and materials

To remove the drum, you need to remove the tank from the machine. This requires removing the top, front, and back panels of the machine, removing the motor, disconnecting all wiring from the plastic tank, etc. During this process, you'll need to have the following on hand:

- a couple of screwdrivers - slotted and Phillips;

- set of wrenches;

- a hacksaw for metal or a cut-off saw (if the tank of your automatic machine is non-dismountable);

- screwdriver;

- hammer;

- punch.

It's also helpful to buy WD-40 aerosol spray. The spray will help remove stuck parts and fasteners. Once you've gathered all the necessary tools, you can begin the repair. Be sure to disconnect the power to the washing machine before disassembling its body.

Let's "halve" the tank

Many people are concerned about how to remove the drum from their washing machine. First, you need to move the machine away from the wall to ensure easy access from all sides and disconnect it from the power supply. Here's the procedure:

- remove the top cover of the case;

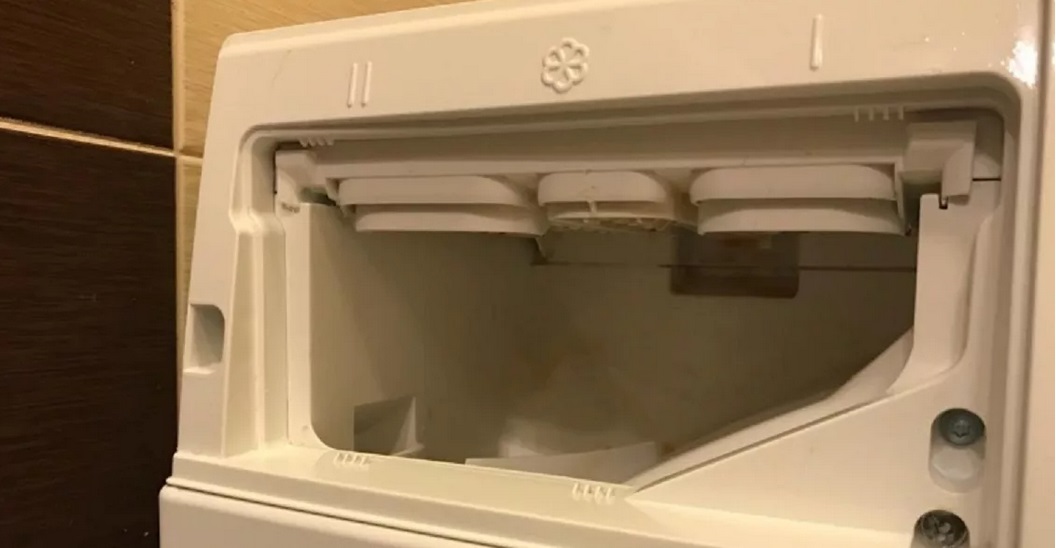

- remove the powder container;

- remove the bolts that hold the control panel;

- remove the dashboard by disconnecting the wiring from it;

- remove the lower decorative false panel;

- remove the clamps holding the drum cuff;

- remove the sealing rubber;

- unscrew the bolts holding the UBL and remove the lock;

- Unscrew the bolts securing the front wall of the case and remove the panel;

- remove the back wall;

- remove the drive belt;

- Disconnect all elements connected to the tank: sensors, pipes, wires, parts;

- Having dealt with the shock absorbers, remove the reservoir from the housing.

The further course of action will depend on what type of tank is installed on your automatic machine. If the tank is collapsible, to separate it in half, you only need to unscrew the screws that hold the two parts together and release the plastic latches. It’s a completely different matter if the tank is “monolithic”.

To remove the drum from the non-separable tank, you will have to saw through the plastic container.

There are several options for cutting a plastic tank. These include:

- hacksaw for metal;

- Bulgarian;

- cut-off saw;

- renovator.

First, use a marker to mark the line where the cut will be made. Some experts recommend cutting the tank in half directly along the factory seam. In this case, the job is easily accomplished with a standard hacksaw.

Most experts recommend sawing the tank from the top to reduce future stress. The sawing path looks like the one shown in the picture.

In this case, it's easier to cut the tank using a chop saw or a renovator. Attach the appropriate attachment to the tool and get to work. It is important to wear safety glasses as hot plastic shavings may fly off the tank during disassembly.

A chop saw or renovator will make a finer cut than an angle grinder, so it's best to use one of these tools to disassemble the tank.

Another advantage of a chop saw is its ability to cut curves. This may be necessary if there's an important structural element on your tank where the cut is to be made that needs to be cut around, such as a stiffener.

If you have a renovator (a multi-tool with various attachments) at home, you can use it to cut the tank. It's more powerful, so it'll be easier to cut the tank in half. There won't be as many plastic shavings flying around during the process.

Removing the drum itself requires some more work. Turn the tank over, place wooden blocks underneath it on both sides, and remove the pulley. Next, apply WD-40 to the drum wheel mounting area and let it sit for 15-20 minutes. Using a punch and hammer, gently tap the center of the drum until it pops off the mounting. This will remove the drum from the machine's tank. Next, replace the worn parts and reassemble everything in reverse order. To fasten the two halves of the tank together, you'll need a soldering iron and a heat gun.

First, use a soldering iron to "tack" the tank halves together on all four sides so that the sawed-off top rim is secured in place. To do this, heat up one and a half to two centimeters of plastic with a hair dryer, then smooth out the soft area with a soldering iron. This ensures the halves are securely bonded together.

Once the entire seam is sealed, you can begin reassembling the machine body. Keep in mind that the sawn-off stiffeners must be repaired as best as possible to avoid impairing the machine's normal operation. Once all the parts are in place, run a test wash and observe how your "home helper" handles the task.

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment