How to remove the drum from a washing machine?

A number of problems may require removing the drum from a washing machine. For example, bearing wear or deformation of the spider. Removing the drum requires almost complete disassembly of the machine. We'll show you how to do it yourself, at home.

A number of problems may require removing the drum from a washing machine. For example, bearing wear or deformation of the spider. Removing the drum requires almost complete disassembly of the machine. We'll show you how to do it yourself, at home.

What will be needed to carry out repairs?

To remove the drum from the washing machine, you will first have to remove the tank. You will need to disassemble the washing machine body by removing the top, front and back panels. After this, the engine, heating element, drain pump and other internal elements are removed from the machine.

The following tools will be useful during the work:

- Phillips and minus screwdrivers;

- set of keys;

- screwdriver;

- small hammer;

- punch;

- a hacksaw for metal or other cutting tool (if the tank of your automatic machine is non-dismountable).

It's also a good idea to have a marker and WD-40 on hand. The spray will help remove stuck fasteners. It's a good idea to have a camera handy and take photos of the work as you go—these photos will help you avoid mistakes when reassembling the washing machine. Once you've gathered everything you need, you can begin the repair.

We remove the tank from the CM housing

Before disassembling the washing machine, it's a good idea to study the machine's manual, specifically to understand the location of its internal components. Knowing the location of the motor, pressure switch, and other components, for example, will make disassembling the components easier.

Be sure to disconnect the power from the washing machine before disassembling the housing.

After unplugging the washing machine, move it to the center of the room. Next, disconnect the appliance from the water supply and sewer system. Then:

- remove the top cover of the washing machine;

- pull out the powder tray;

- unscrew the screws securing the control panel;

- remove the instrument panel, disconnecting the wires supplying it;

- remove the lower decorative panel;

- open the washing machine hatch and remove the clamps securing the drum cuff;

- remove the sealing cuff;

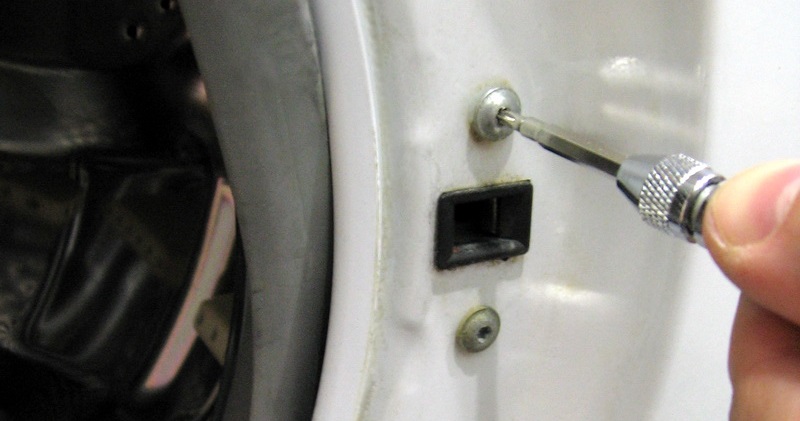

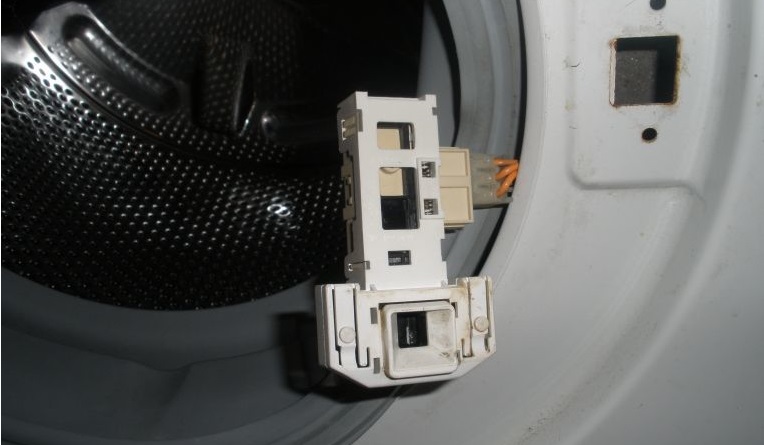

- unscrew the screws securing the UBL and remove the blocker;

- remove the bolts along the perimeter of the front wall of the case, remove the panel;

- remove the rear panel of the machine;

- reset the drive belt;

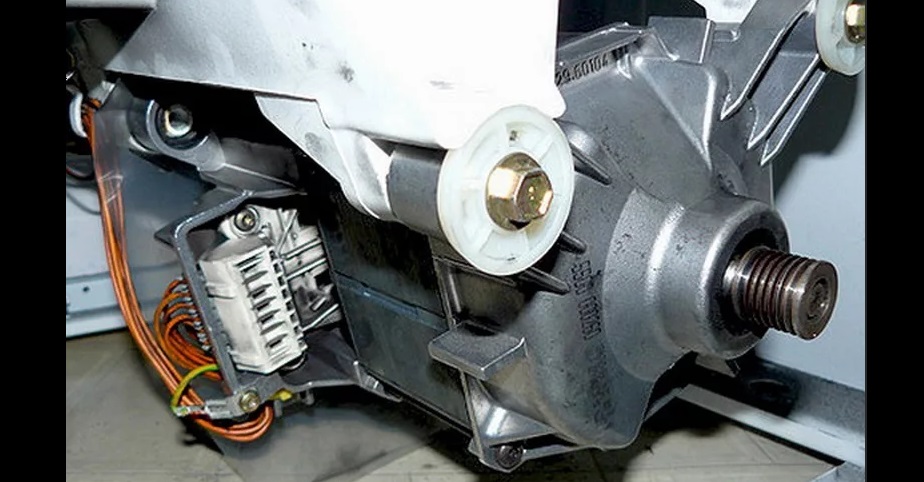

- disconnect all elements connected to the tank: sensors, hoses, engine, pulley;

- Having dealt with the shock-absorbing springs, remove the tank from the housing.

Afterwards, place the tank on a flat, horizontal surface. Now your task is to split the plastic container in half. We'll show you how.

We split the plastic tank in half and remove the drum.

An important detail is whether your washing machine has a split or a solid tank. If it's a split tank, separating it in half shouldn't be difficult. Simply remove the mounting screws, release the latches, and the tank will separate into two halves.

Things are more complicated if your washing machine's drum is non-detachable. In this case, you'll have to saw it off. This can be done using the following tools:

- hacksaw for metal;

- renovator;

- Bulgarian;

- cut-off saw.

It is recommended to saw a non-separable tank exactly along the weld seam.

First, you need to mark the cut line. Take a marker and draw a line. Next, arm yourself with your tools. Be sure to wear safety glasses to prevent flying wood chips from getting into your eyes while you work. A resurfacing saw and a cut-off machine cut thinner than an angle grinder, so it's recommended to use these tools.

Another advantage of a cut-off machine is the ability to cut curves. This makes it easy to avoid important structural elements on the tank, such as stiffeners.

Once the tank is cut, proceed further. Remove the top "empty" section and place boards on both sides under the bottom section. Remove the pulley.

Next, spray the pulley mounting area with WD-40. Wait 10-20 minutes for the solution to take effect. Take a drift and a small hammer and tap the center until the drum pops out of the plastic container.

This completes the drum removal process. Now you can begin troubleshooting: replacing the bearings, seal, or spider. Once the repair is complete, you'll need to reassemble the assembly.

Place the drum back into the lower half of the tank. Reattach the pulley. To join the two halves of the plastic container, you will need a hair dryer and a soldering iron.

Place the top half of the tank on the bottom and solder the rims in four or five places. This is to prevent the cut-off half from moving. Then, gradually secure the tank, heating 2 cm of plastic with a hair dryer and smoothing the softened area with a soldering iron.

Experts recommend additionally securing the tank halves with bolts, spaced 5-10 cm apart, for added security. If soldering is undesirable, a special silicone sealant can be used. In this case, you will need:

- clean up the cut areas on both halves of the tank;

- apply heat-resistant sealant around the circumference;

- place the parts of the tank on top of each other;

- Place a weight on top and wait until the mixture dries completely.

Once the halves of the plastic container are joined, you can begin assembling the automatic washing machine. This is done in the same way, in reverse order. First, install the tank, connect the pipes and components, and then replace the main components: the motor, pump, heating element, pressure switch, etc. It's best to refer to the photos you took earlier to avoid mistakes.

Next, you need to activate the test cycle. Observe the machine's operation. There should be no unusual noises or leaks. If everything is normal, you can run a regular wash with the laundry in the drum.

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment