How to seal a rubber hose on a washing machine?

A washing machine is full of pipes and hoses, and water constantly circulates through them. The problem is that over time, high temperatures, natural wear, dirt, and vibration cause the rubber to dry out and break. This eventually leads to leaks, which threaten the entire system and your home. A leaking washing machine should not be used: you must either seal the rubber hose or replace it with a new one. Let's figure out the safest solution and what to do.

A washing machine is full of pipes and hoses, and water constantly circulates through them. The problem is that over time, high temperatures, natural wear, dirt, and vibration cause the rubber to dry out and break. This eventually leads to leaks, which threaten the entire system and your home. A leaking washing machine should not be used: you must either seal the rubber hose or replace it with a new one. Let's figure out the safest solution and what to do.

How to reliably patch a pipe?

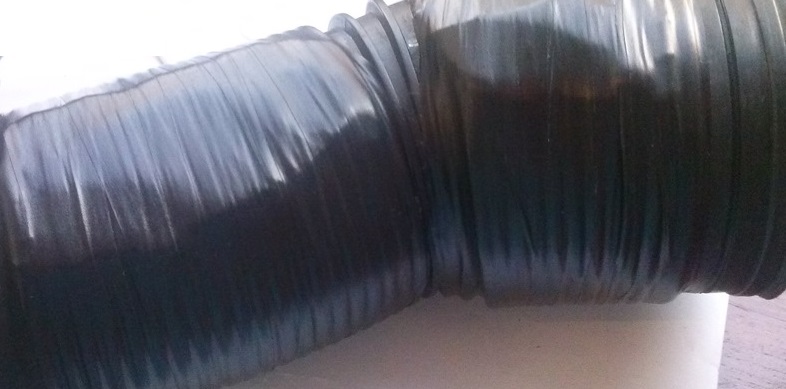

You can seal the pipe, but only temporarily. Even the best patch can cause a leak, especially if the repair is done quickly and poorly. The safest thing to do is to refuse repairs, buy a whole hose and replace the old one. If purchasing new components isn't currently possible, you can make do with improvised means. There are several ways to repair the hose. Below are the most reliable and popular options.

- Duct tape. The easiest way is to wrap the damaged area of the hose with a thick layer of duct tape. The key is to tape 10 cm before and after the tear, using plenty of tape. However, this option isn't very reliable; it's best to replace the hose as soon as possible.

- Thread. The patch will be stronger if the crack is stitched with thick shoe thread. The stitching should be done in a herringbone pattern, with large stitches, pulling the hole together. Afterward, the entire "creation" is generously coated with sealant. This type of patch lasts a long time and can be used even on curved areas of the part.

Simply sealing a torn pipe with electrical tape is not enough – water will quickly start leaking!

- Shunt tube. A hole in a straight section of the hose can be patched using a plastic tube of the same diameter as the hose. Trim the corrugated tube, exposing the insides, and insert the nozzle so that it extends into the hose at least 3 cm on both sides of the hole. Then, secure the ends of the tube with steel clamps over the rubber.

If replacing the torn hose is temporarily unavoidable, consider a patch made of thread and sealant or a tube. In the latter case, a patch will be the most reliable—water will flow through the improvised bypass, bypassing the hole. However, it's better to avoid risks and install a new hose as soon as possible.

Replacing the pipes between the valve and the dispenser

If you notice a puddle under your washing machine, you should immediately check for the leak. The first step is to check the dispenser hose. Remove the top cover of the machine and locate the hose in the left corner that connects the fill valve to the detergent drawer. The hose is secured with clamps tightened at both ends. To ensure it is intact, follow these steps:

- Using pliers, loosen both clamps;

- move the “rings” to the middle of the pipe (do not tear them off, they are reusable and will come in handy during reassembly);

- disconnect the pipe from the inlet valve fitting;

- remove the hose from the powder receiver fitting;

- Carefully inspect the hose for cracks, blockages and other defects.

The pipes must be intact, clean and flexible – otherwise there is a high risk of leakage!

If the rubber is intact and flexible, simply rinse it in warm water and scrub the corrugated tube with a bottle brush. Then, return the tube to its original position and secure it with clamps. A damaged or hardened hose must be replaced - an equivalent is selected based on the serial number of the existing washing machine.

Replacing the filler pipe

The hose connecting the tank to the detergent drawer often fails. More often than not, the problem isn't cracks, but rather a blockage—some detergent settles in a thick layer on the surface of the hose. As a result, the washing machine stops running, or the hose ruptures due to increased pressure. Owners of modern LG washing machines have the easiest time removing and inspecting the inlet hose: simply unscrew the top cover, locate the hose, and release the clamps. On the vast majority of machines, this inspection requires removing the front panel first. The instructions are as follows:

- disconnect the washing machine from the utilities;

- remove the top cover;

- remove the powder receptacle;

- unscrew the bolts located in the recess from the tray and along the perimeter of the dashboard;

- carefully pry up the dashboard with a screwdriver, press the latches and, without disconnecting the wiring, place the panel on top of the car;

- slide the technical hatch door off the latches;

- open the hatch and loosen the outer clamp on the cuff;

- tuck the cuff inside the drum;

- unscrew the screws holding the UBL;

- loosen the screws securing the end around the perimeter;

- Pull the front panel towards you – it will immediately “come off” from the grooves.

The inlet hose is easy to find—it connects the washing machine to the detergent dispenser. To remove the hose, loosen the clamps holding it in place and unhook it from both fittings. Afterward, inspect the hose for damage or blockages. If everything is clean and intact, we put it back in place; if it is clogged, we clean it with a brush; if it is torn, we replace it with a new one.

Replacing the drain pipe

The drain hose located between the wash tub and the drain pump often leaks. The explanation is simple: this tube carries not only soapy water and detergent residue, but also any debris that gets into the drum. Sometimes a crack appears due to simple wear and tear, while other times it's caused by a sharp foreign object.

Inspecting and replacing the drain hose is easy, especially if your washing machine doesn't have a drip tray. In this case, simply lay the machine gently on its side. It's important to choose the side with the dispenser, otherwise any remaining water in the detergent drawer will drip onto the control board. If your washing machine has a drip tray, you'll need to remove it first. Keep in mind that many modern machines support the Aquastop system: in this case, you'll need to carefully disconnect the wiring leading to the float. The rest is simple:

- loosen the clamps;

- remove the hose from the fittings;

- We inspect for blockages and defects.

If the hose is clogged with scale and debris, clean it or soak it for 2-3 hours in a warm lemon solution. If there are cracks in the rubber, it's best to replace the corrugated hose immediately rather than experiment with patches.

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment