Replacing shock absorbers on a Siemens washing machine

Every washing machine is equipped with a shock-absorbing system. Dampers are mounted beneath the wash tub, and springs are tensioned above. This ensures that the machine absorbs the vibrations and oscillations that occur during the washing and spinning cycles. If the machine loses its former quietness and stability, and begins to rattle and bounce, the dampers are damaged and no longer perform their intended function. In this case, the shock absorbers in the washing machine need to be replaced.

Every washing machine is equipped with a shock-absorbing system. Dampers are mounted beneath the wash tub, and springs are tensioned above. This ensures that the machine absorbs the vibrations and oscillations that occur during the washing and spinning cycles. If the machine loses its former quietness and stability, and begins to rattle and bounce, the dampers are damaged and no longer perform their intended function. In this case, the shock absorbers in the washing machine need to be replaced.

How are these elements structured?

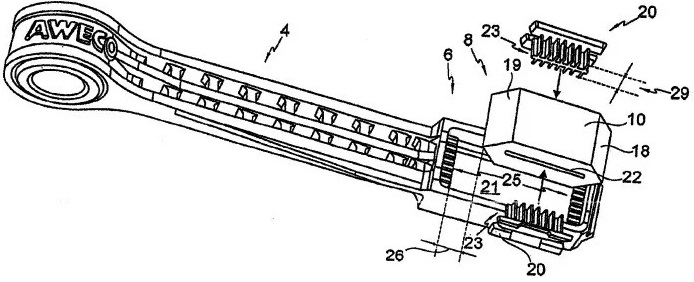

You can replace shock absorbers at home without going to a service center. Just follow the instructions and observe safety precautions.Ideally, before starting a repair, it's worth familiarizing yourself with the design and operating principles of pistons. Modern Siemens machines are equipped with friction dampers, which are ideal for centrifugal-type machines. These dampers consist of several components. The key ones are:

- fixed body;

- a moving piston pusher, slightly protruding from the body;

- a movable plate through which the spacer is fixed;

- a guide that is under tension and ensures the movement of the mechanism in the desired direction;

- sliding surface located between the lining and the guide;

- spacer.

The damper operates using the resistance generated by the movement of its components. This well-coordinated mechanism smoothly dampens the vibration generated by the rotating drum, absorbing the brunt of the centrifugal shock. Unlike previously used shock absorbers, modern struts do not have return springs, resulting in a longer service life.

On average, the dampers on Siemens washing machines last 5-7 years.

Some Siemens models are equipped with shock absorbers. These struts have a fairly standard design: a cylinder is housed within a fixed housing, and a moving piston rod is fixed within the housing. To ensure perfect interaction, rubber and polymer gaskets are applied, treated with a special lubricant. They ensure optimal sliding, smoothing out mechanical vibrations.

The damper is secured in two places: the housing is attached to the bottom of the machine with a silent block (a rubber-metal hinge bushing), and the sliding rod is screwed to the wash tub. Longitudinal movement is essential, for which sliding supports are installed nearby. These supports are secured with dowels to prevent axial movement.

How does a shock absorber failure manifest itself?

On average, the original shock absorbers in Siemens washing machines last 5-7 years without fail. However, some shock absorbers operate reliably for even longer, while others, on the contrary, barely last 1-3 years. This depends on the machine's operation and build quality. The following factors can cause shock absorber failure:

- natural wear of rubber components (seals);

- long-term loads and constant vibrations;

- drying out or washing out of the lubricant provided in the shock absorber housing;

- Violations of Siemens operating rules.

Most often, premature damage to dampers is caused by careless operation of the equipment. Constantly overloading the drum, prolonged spinning at maximum speed, and washing with imbalance significantly reduce the service life of the racks. You can suspect a shock absorber failure based on the following symptoms:

- The Siemens body vibrates strongly, especially when the spin cycle is turned on at high speed;

- the washing machine constantly knocks and “jumps” around the room;

- the drive belt often slips off the pulley;

- leaks occur through the hatch (the drum hits the body of the washing machine, the rubber seal wears out and begins to leak water).

Severe vibration, knocking, leaks, and a belt coming off may indicate problems with the dampers.

You can't immediately blame the shock absorbers—other problems can show similar symptoms. However, checking the shock absorber system is essential. Testing the shock absorbers is quite simple: remove the top cover, apply pressure to the tank, and observe its behavior. If the tank returns smoothly, there's no problem with the shock absorbers. If the drum responds to pressure with jerks or erratic rocking, the pistons need replacing.

You can finally verify the dampers' proper functioning by inspecting them. But first, you need to remove the struts. This is difficult, but quite possible to do at home.

Opening access to details

Removing the dampers requires partial disassembly of the machine. Therefore, the repair begins with preparing the appliance: disconnect the Siemens from the power supply, secure the hoses and cord to the back wall, and then move the washing machine to the center of the room. Next, follow the instructions:

Before disassembling the washing machine, make sure that the appliance is disconnected from the power supply, water supply, and sewerage system!

- unscrew the top cover;

- we take out the dispenser;

- we unscrew the bolts and other fasteners “hidden” behind the tray that hold the instrument panel;

- disconnect the board from the case (be careful with the wiring - do not damage it);

- we lower the machine onto the back wall;

- loosen the screws that secure the bottom;

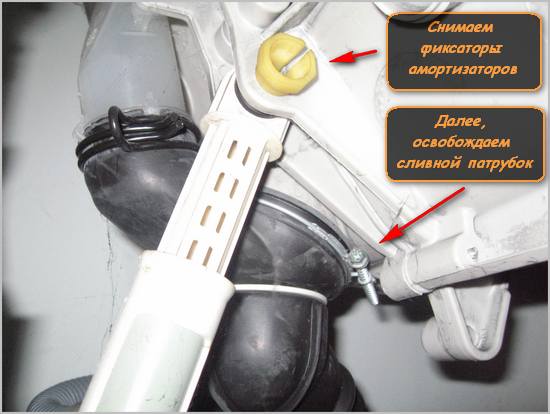

- open the hatch and remove the outer clamp from the cuff;

- we insert the cuff into the drum;

- we detach the end from the body, simultaneously disconnecting the wiring from the UBL.

After removing the front panel, you'll see the shock absorbers—two pillars that secure the drum. Ideally, to remove the shock absorbers, you'd continue disassembling the machine until you remove the washing tank. However, DIYers can simplify the task by removing the pistons now that the Siemens is lying down with the drum still in place. It's more difficult, but it's much faster.

We change parts

To replace the dampers, you need to remove the old ones—unhook them from the body and the wash tub. From below, it's easy: just loosen the fasteners. At the top, special plastic holders are used to secure the racks. They cannot be unscrewed in the usual way, so when removing the shock absorbers, we proceed as follows:

- take a 13 mm drill;

- insert the drill into the screwdriver;

- We carefully drill the fasteners, releasing the pistons.

Old shock absorbers cannot be repaired. They are disconnected and disposed of in the prescribed manner. The freed-up seat is then cleaned and treated with a lubricant/sealant. Then, new shock absorbers are installed: bolted to the transmission body from below and attached to the gas tank from above through previously drilled holes.

Once the shock absorbers are installed, screw the previously removed components back into place and return the Siemens to its upright position. Be sure to test the new shock absorbers by running a test wash. If the washing machine stops vibrating and making knocking sounds during the spin cycle, the shock absorber replacement was successful.

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment