How to replace a washing machine motor?

The motor is a key component of a washing machine; without it, the drum won't spin. If it breaks, the machine malfunctions, requiring repair or replacement to restore proper operation. This procedure is expensive at a service center, so it's best to first try to fix the problem yourself. Removing and replacing a washing machine motor yourself is easy. The key is to know the step-by-step procedure and remember safety precautions.

The motor is a key component of a washing machine; without it, the drum won't spin. If it breaks, the machine malfunctions, requiring repair or replacement to restore proper operation. This procedure is expensive at a service center, so it's best to first try to fix the problem yourself. Removing and replacing a washing machine motor yourself is easy. The key is to know the step-by-step procedure and remember safety precautions.

What kind of engine are we dealing with?

Before disassembling and repairing your washing machine's motor, you should determine its type and design features. These parameters will determine the sequence of actions and the duration of the diagnostics. As a rule, automatic machines are equipped with three types of motors: asynchronous, collector or inverter.

- Asynchronous. It features a simple design, low cost, and ease of maintenance. It consists of a stationary stator and a rotor that spins the drum via a belt drive. It can be two- or three-phase, depending on the number of winding layers on the housing. The main drawback of this motor is its lack of power, which manifests itself in weak shaft rotation, sudden speed drops, and partial rotations. All of this negatively impacts washing performance, which is why asynchronous motors are now extremely rare in washing machines.

Modern machines are equipped with a collector or inverter motor.

- Commutator. This consists of a stator, rotor, winding, and tachogenerator. Current is supplied to the armature by a pair of brushes, which generate an electromagnetic field, causing the shaft to rotate. The rotation speed depends on the electrical voltage. The commutator is located under the washing tank, and the impulse is transmitted to the pulley via a belt drive. This type of motor also has its drawbacks: brushes wear out over time and the drive belt slips.

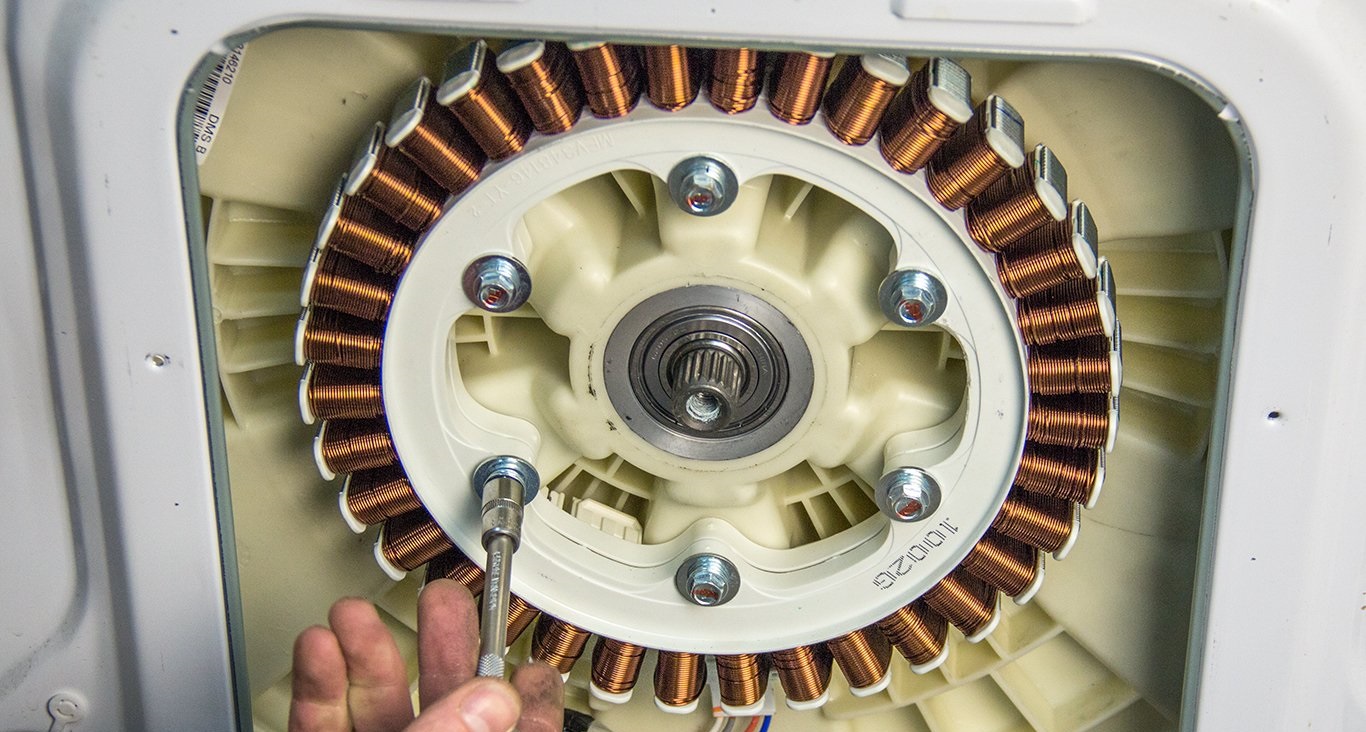

- Inverter. The most modern motor, whose main distinguishing feature is its direct drive. These motors are reliable, highly efficient, and come with a ten-year manufacturer's warranty. However, they do have a weak point: the mechanism is installed next to the bearing assembly, and if the bearing fails, it often becomes flooded and fails.

Asynchronous motors are almost never found in modern washing machines; machines are more often equipped with inverter or commutator motors. While the latter rarely fails, the carbon brushes on the commutator motor need to be checked regularly. In any case, it's important to know how to diagnose and remove the motor.

Dismantling and installation of various motors

Most budget washing machines have a commutator motor, which is significantly cheaper than an inverter motor. The commutator must be removed and repaired more frequently to monitor the condition of the carbon brushes. Disassembly begins with partial disassembly of the machine. The instructions are as follows:

- disconnect the machine from the power supply;

- wait until the equipment is completely de-energized;

- ensure free access to the engine (remove the back panel on washing machines from Ariston, Zanussi, Indesit, Beko or the front panel on Bosch, Samsung, LG);

- pull the drive belt off the drum pulley;

- find the electric motor under the tank;

- disconnect the wiring (phase and ground) from the engine;

- Use a suitable wrench to loosen the motor holding bolts;

- loosen the engine body (it often “sticks” to the mounting surface);

- remove the engine from the socket.

This completes the electric motor removal and begins its repair. It's also easy to reinstall the motor yourself. Simply reverse the steps described above.

Dismantling the inverter motor

Inverter motors rarely fail. It's strongly recommended that you don't attempt to open up a direct-drive washing machine, diagnose it, or replace the motor yourself—it's safer and easier to call a professional repairman. However, if you prefer, you can remove the motor at home. The procedure for removing an inverter motor is as follows:

- de-energize the machine;

- remove the front or back panel from the washing machine body (depending on the brand of the machine);

- take a photo of the location of the wiring connected to the engine;

- disconnect the wires from the terminals;

- loosen the motor holding fasteners;

- unscrew the bolt securing the rotor, holding it with your hand;

- remove the rotor assembly, and then the stator;

- unhook the remaining wires.

Before dismantling the motor, be sure to de-energize the machine!

You should be extremely careful: the direct drive is extremely sensitive to mechanical damage. Ideally, you should film all your actions on camera to avoid mistakes during reassembly.

Dismantling the engine using cheap activator equipment

It's a different matter if you need to access the motor in a Malutka washing machine or similar compact vertical washing machines. These machines are called activator-type machines—they have an activator installed on the electric motor shaft that spins the water and laundry. Due to their unique design, the machine is disassembled differently:

- the plug is removed from the housing, under which the engine is “hidden”;

- the activator is turned by hand so that the hole in the impeller aligns with the groove in the rotor;

- the rotor is locked with a screwdriver through the nearby hole;

- the activator is removed;

- the drive is pulled out;

- the motor is released.

Replacing the engine yourself is entirely possible. Just follow the instructions carefully.

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment