How to replace the drum flange of a top-loading washing machine

The drum flange is considered a weak point in vertical automatic washing machines. If it's damaged, owners can expect costly repairs. Can I replace the part myself? What will be required during the repair? Let's explore the details.

The drum flange is considered a weak point in vertical automatic washing machines. If it's damaged, owners can expect costly repairs. Can I replace the part myself? What will be required during the repair? Let's explore the details.

What will be needed for repairs?

It is quite possible to replace the drum flange yourself, at home. To repair it, you will have to disassemble the top-loading washing machine and remove the drum. The following tools will be needed during the process:

- slotted and Phillips screwdrivers;

- screwdriver or drill;

- drills with a diameter of 5 and 6 mm;

- six bolts with a pin and washer (M5 or M6);

- spanner.

To replace the drum flange, you need to remove the tank from the vertical machine body. Here's how:

- de-energize the washing machine;

- disconnect the vertical unit from the water supply and sewerage system;

- Use a screwdriver to unscrew the fasteners securing the back wall of the washing machine;

- remove the back panel;

- move the side panel of the case to the side and remove it too;

- disconnect all pipes and wires from the tank, having first photographed the position of each element;

- remove the screw holding the shaft;

- Close the loading door and remove the tank.

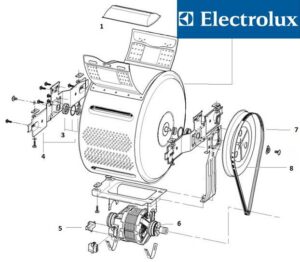

Next, you need to disassemble the tub and remove the drum. On top-loading washing machines, this is done the same way as on front-loading machines. Now you can begin replacing the flange.

Removing a damaged flange

The drum flange is the support for top-loading washing machines. It is installed on the opposite side from the pulley and secured with a set of fasteners. The old element may break during removal, and this is not a problem.

When purchasing a flange and repair kit, you need to focus on the model and serial number of your top-loading washing machine.

The easiest way to order components is online. Today, online stores offer customers absolutely any parts for automatic washing machines, both front-loading and top-loading. You can also try searching for a flange at local retailers. The average cost of a part is $10–$15.

The old flange may be severely damaged, so be prepared for this. To remove it, take a drill or screwdriver and insert a drill bit into the tool. Next:

- drill out all 6 rivet fasteners on the flange using a 5mm drill bit (this should be done at low speeds to prevent the drill bit from overheating);

- change the drill bit, installing a six-millimeter one in the drill;

- drill the same holes with a 6 mm drill.

These actions will remove the fasteners and destroy the flange. This allows for simple removal of the old part. Before installing the new component, the mounting surface must be cleaned of any debris, dirt, or limescale.

Installing a new flange and assembling the machine

The next step is installing the new flange. You'll need six bolts with a washer and a wrench of the appropriate size. The rest of the procedure is as follows:

- Place the new flange in place, aligning the holes on the part with the drilled holes on the drum;

- screw the bolts through the engraver into the holes (the flat side should be inside the drum so that in the future the laundry does not get caught on the protruding washers);

- Tighten each washer with a wrench.

The main difficulty when replacing the drum flange is not the removal and installation of the part itself, but rather the disassembly of the washing machine. To replace the element, you'll have to remove the drum from the vertical washer and then reassemble the housing.

After installing the new drum flange, reassemble the top-loading washing machine. Follow these steps:

- insert the drum into the lower half of the tank;

- install the top of the tank, assemble the container;

- place the oil seal on the shaft, treat the rubber with a special lubricant, and place the sealing sleeve on top;

- install a horizontal metal bar on top and secure the structure with screws;

- put another previously removed metal strip back in place and secure it with three bolts;

- install the pulley, securing the “drum wheel” with a screw;

- Turn the tank over and perform the same actions on the other side (install the oil seal and the sealing bushing, treat the unit with grease, install the metal strips);

- Spin the drum, make sure that nothing is interfering with its rotation;

- Place the drum-tank assembly into the washing machine body;

- connect all previously disconnected parts, pipes and wires to the tank;

- Fix the side wall of the case and the rear panel of the "vertical".

Once assembly is complete, run a test wash and observe the operation of the washing machine.

If everything is done correctly, the machine will operate without any problems. There should be no unusual noise when the drum rotates. After the test wash, you can use the vertical washer as usual.

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment