How to replace a bearing in an ASKO washing machine

Washing machines from the Swedish brand ASKO are considered extremely reliable. The machine body is made of high-strength material, and the drum is made of high-quality metal. However, even such durable washing machines can fail, especially after several years of use.

Washing machines from the Swedish brand ASKO are considered extremely reliable. The machine body is made of high-strength material, and the drum is made of high-quality metal. However, even such durable washing machines can fail, especially after several years of use.

A typical problem is bearing failure. Various factors can cause this failure: normal wear and tear, constant overloading of the washing machine, frequent drum imbalance, etc. We'll explain how to replace a bearing in an ASKO washing machine and delve into the nuances of the upcoming repair.

Disassembling the Asko washing machine

Before starting repairs, you need to realistically assess your capabilities. To change the bearings, you will have to almost completely disassemble the washing machine. Unlike other brands, Asko doesn't require removing the metal tank from the machine body; simply pull out the drum. But first things first.

Removing worn bearings is no easy task. Knocking out the rings requires specialized tools. First, you'll need a puller. Second, you'll need an adjustable wrench and a box-end wrench. You'll also need screwdrivers, a ratchet, a drift, a hammer, a metal pin approximately 25-30 cm long and about 2 cm wide, a screwdriver, a knife, and sealant. All the tools are shown in the image below.

The next step is preparing the machine. Move the washing machine to the center of the room to ensure easy access to all sides of the unit. Be sure to disconnect the power before moving it. You'll also need to close the shut-off valve on the water pipe and disconnect the washing machine from the water supply and sewer lines.

The further algorithm of actions will be as follows:

- remove the top cover of the washing machine housing;

- remove the back wall of the machine;

- remove the detergent drawer from the washing machine;

- remove the machine door, having first disabled the door locking device;

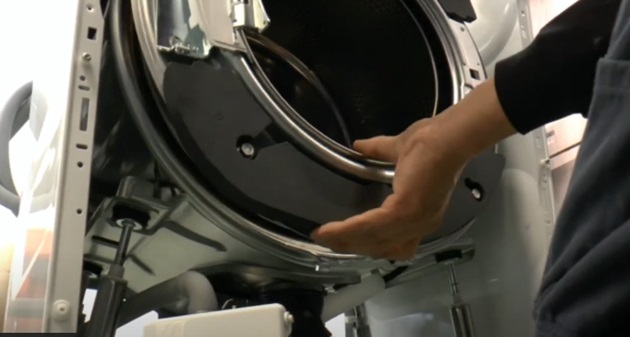

- remove the front wall of the washing machine housing;

- loosen the clamp that regulates the tank, remove the metal ring;

- remove the metal rim with counterweight located in front of the drum;

- Using a socket wrench and a hammer, remove the bolt securing the pulley;

- remove the drive belt;

- Using a puller, carefully remove the bolt and bearing from the rear of the tank;

To avoid stripping the threads, it is better to put a little grease on the nut and the puller itself.

- After the rear bolt is removed, pull the drum out of the washing machine housing.

Asko washing machines have a unique bearing replacement process. The standard procedure eliminates the need to remove the tank from the housing and divide it into halves. Therefore, there's no need to disconnect the motor, hoses, or wires from the tank. This makes the job a bit easier.

Removing the old bearing and installing a new one

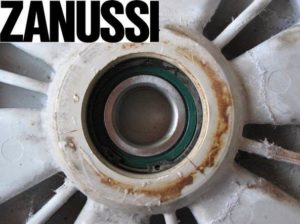

Once the drum is removed, access to the inner bearing will be available. It's easier to remove than the rear ring. First, use an adjustable wrench to pry up and remove the metal cover covering the assembly.

This will give you access to the oil seal. Remove the rubber seal. The inner bearing is located under the gasket.

The inner bearing is knocked out with a punch and a hammer from the rear of the tank. If the ring cannot be removed this way, use a special tool called a puller.

New bearings and seals are purchased for a specific model of Asko washing machine.

Before installing new components, it's important to clean the mounting surface of any debris or dirt. You can spray the area with WD-40 spray lubricant. Then, wipe the area with a clean, damp cloth.

The Asko washing machine repair kit includes bearings, a seal, and grease. Generously lubricate the rubber seal before installation to prevent water from entering the unit. Place the new metal rings in place and tap them lightly with a hammer.

The nuances of reverse assembly

Once you have installed new bearings, you can reassemble the washing machine. Asko machines have one caveat: after such repairs, a check for play is mandatory.It is necessary to make sure that the washing machine tank does not sag.

Next, the same sequence of actions is performed, but in reverse order. The bearing assembly is covered with a metal cover. The drum is replaced. First, the shaft is cleaned and a thin layer of bearing grease is applied.

Next, the drum pulley is installed. It is secured with the previously removed bolt and nut. The fastener must be tightened securely, but it's important not to overtighten it.

The further algorithm of actions will be as follows:

- tighten the drive belt on the drum and engine pulley;

- replace the drum seal if necessary;

- put the front part in place, in which the drum sealing cuff is “hidden”;

- Align the loading hatch using a special device;

- put the front rim and counterweight back in place;

- Secure the structure with a metal clamp. To tighten the clamp, gently press it with a hammer;

- install the hatch door, secure it and connect the locking device;

- put the front panel of the case back in place;

- put the powder receptacle back in.

Before fully reassembling the washing machine, we recommend running a test cycle to check for leaks. Connect the inlet hose; the drain hose can be directed into a basin or bathtub. Select the shortest program, such as "Rinse + Spin." Monitor the machine closely to ensure prompt response to any leaks.

If the cycle proceeds normally, the bearing replacement is complete. Completely reassemble the washing machine, securing the back and top panels. Afterward, move the Asko unit to its usual location and connect it to the water supply and sewer lines.

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment