How to change a bearing in a Leran washing machine?

It's quite easy to tell when it's time to replace your washing machine's bearings. This type of malfunction has characteristic symptoms. Your "home helper" will begin making a knocking noise during operation, with the noise intensifying during the spin cycle. Further signs include looseness in the drum, rusty stains on the tub, and strong vibrations in the housing.

It's quite easy to tell when it's time to replace your washing machine's bearings. This type of malfunction has characteristic symptoms. Your "home helper" will begin making a knocking noise during operation, with the noise intensifying during the spin cycle. Further signs include looseness in the drum, rusty stains on the tub, and strong vibrations in the housing.

How do you replace a bearing in a Leran washing machine? How difficult is the job? Can you handle the repair without a professional? Let's explore the details.

First, diagnostics

The work ahead cannot be called easy. To replace the bearing, you will have to almost completely disassemble the washing machine. Leran. It would be a shame if, after much effort, you discovered the bearing assembly was perfectly fine. Therefore, it's essential to begin with diagnostics.

The following signs indicate the need to replace the bearing:

- the machine knocks when working;

- when you rotate the drum by hand, you can hear a grinding and clanking sound;

- there is significant play in the drum (you can determine whether this is the case by shaking the container with your hand in different directions);

- the washing machine displays a corresponding error;

- There are rusty stains on the back wall of the tank (to check this guess, you need to remove the back panel of the Leran washing machine case).

Sometimes the work isn't limited to just replacing the bearing. In some cases, the universal joint or shaft may be damaged. This will increase the cost of the repair, and additional components will need to be purchased.

What do we do to remove the tank with the drum?

Although the job is labor-intensive, it's within anyone's capabilities. The key is to follow the instructions carefully. For the repair, you'll need a Phillips-head and flat-head screwdriver, a cordless drill, a small hammer, a drift, and a set of wrenches.

Before disassembling the washing machine, disconnect the appliance from the power supply, water supply and sewerage system.

Next steps:

- unscrew the 2 screws holding the washing machine cover;

- remove the top panel of the automatic machine body;

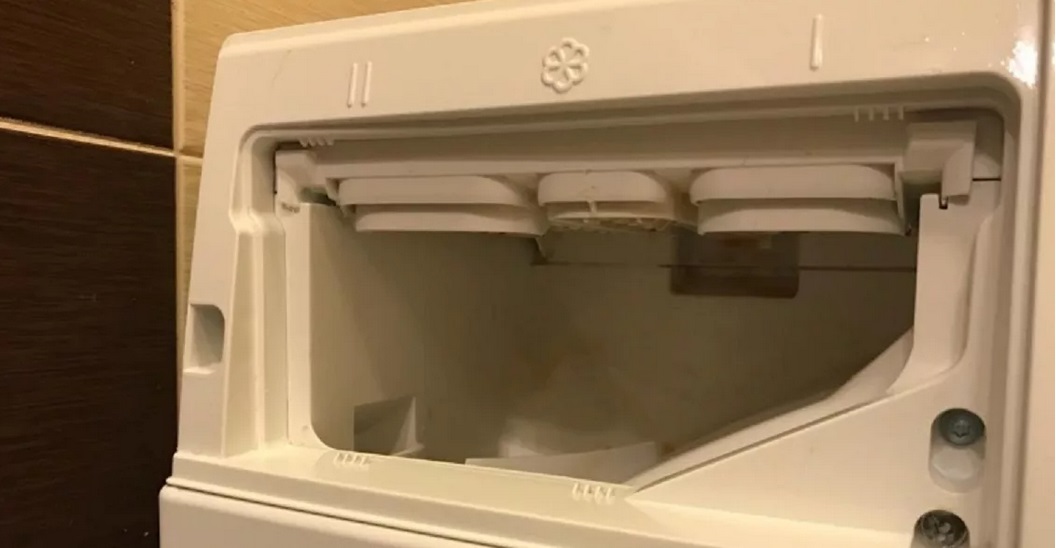

- remove the powder tray from the machine;

- remove the screws securing the control panel;

- carefully place the dashboard on top of the machine or hang it on the side (you can completely detach the control panel, but before doing this you need to take a photo of the wiring diagram);

- detach the lower false panel from the washing machine body;

- unscrew the waste filter, first placing a container underneath it (this will allow you to drain the remaining waste liquid from the system);

- After unscrewing the screws, remove the back wall of the case;

- remove the drive belt from the pulley;

- Use a screwdriver to loosen the wire clamp of the drum cuff and remove the ring;

- insert the sealing rubber into the drum;

- After removing the screws, dismantle the front panel of the case.

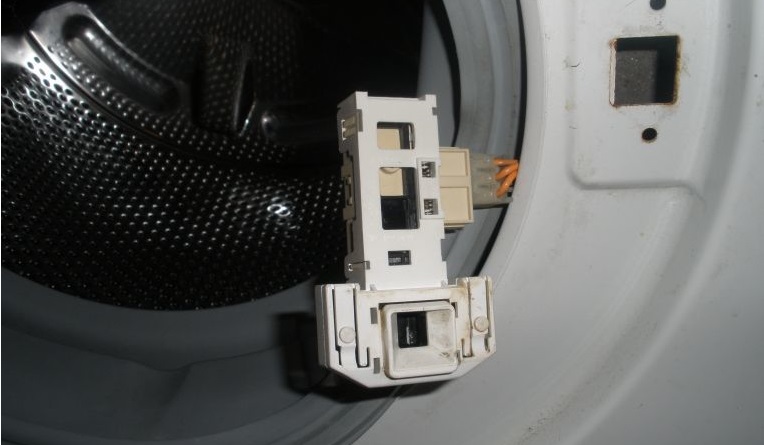

The hatch locking device will interfere with removing the front panel. Take a photo of the contact connection diagram and then carefully remove them. After that, you can easily remove the hatch locking device.

Next, you need to disconnect all internal elements that interfere with the removal of the tank:

- unhook the filler neck;

- unfasten the wire connected to the dispenser, as well as the pipes, remove the hopper from the body;

- remove the top metal strip (it will be accessible after disconnecting the dashboard);

- remove the upper counterweight;

- remove the pressure switch (it is necessary to take into account that on Leran machines the level sensor is additionally secured with a bolt);

- disconnect the thermistor by resetting its terminals;

- disconnect the wires from the heating element;

- remove the tubular heater from the machine;

- disconnect the motor by unscrewing the screws that secure it;

- Unhook the drain pipe from the tank (on Leran, in addition to the clamp, it is also secured with a separate bolt).

Now there will be nothing to hinder the removal of the drum-tub assembly from the Leran washing machine. Once the shock absorbers are removed, remove the drum from the washing machine. The parts are heavy, so you may want to call an assistant.

Removing and disassembling the tank

The next steps are performed after the tank is removed. Place the plastic container on a flat surface, pulley side up. Then, unscrew the nut holding the drum wheel. The rod is pressed inward, after which the drum itself can be removed.

The tank of Leran washing machines is detachable.

The disassemblable tank greatly simplifies bearing replacement. No sawing is required. Simply unscrew the screws around the perimeter of the plastic tank and separate it into two halves.

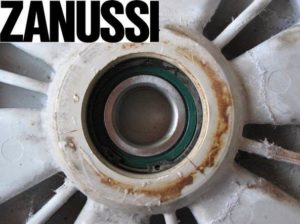

Now you can inspect the universal joint and the shaft itself. Make sure the parts are not deformed. There should be no wear on the components. If everything is in order, you can continue with the repair as planned.

If the universal joint and shaft are in poor condition, it's best to replace them immediately. Purchase components for your specific Leran model, using the serial number and markings of the old parts as a guide.

Next, you can begin to remove the rings. To remove the bearings you will need a small hammer and a punch. Algorithm of actions:

- remove the oil seal (sealing gasket);

- place the end of the drift in the center of the rear bearing;

- carefully tap the ring, hitting the punch with a hammer (the metal rod must be constantly moved, you cannot hit the same place);

- knock out the second bearing in the same way.

Afterwards, the bearing surface is cleaned of dirt and rust. It's also important to wipe the drum shaft clean and polish it if necessary. Once the cleaning is complete, you can begin pressing in the new bearings.

Installation of new parts

Components are selected specifically for your Leran machine. It's best to buy genuine parts rather than Chinese knockoffs. If you order bearings online, check the specific model they're intended for. The same applies to the oil seal.

You can also go to a specialty store with the rings already removed. This way, you'll be less likely to make a mistake when selecting bearings and seals. The seller will be able to provide similar parts.

First, install the smaller-diameter bearing, which is located on the outside. The ring is pressed in using a drift and hammer. The rod should only be pressed against the outer bearing race. The direction of the drift should also be varied regularly.

You must not knock on the inner race of the bearing - this can easily destroy the ring.

Once one element is pressed in, you can install the inner bearing. It is also driven in with a hammer, into the outer race, through the spacer. Proceed carefully, without applying excessive force.

Next, the oil seal is installed. It's best to use superglue to secure the rubber seal. The top of the gasket is generously coated with a special bearing grease. This will prevent water from entering the unit, thereby extending the life of the assembly.

Then, the drum bushing itself is treated with grease. After this, you can begin assembling the assembly. Be careful—this joint cannot be assembled with any play. It will fall apart after a couple of cycles. The bearing must be firmly seated.

If the bearing fits onto the shaft without any effort and has play, it needs to be punched. This will ensure a secure connection. Next, assemble the tank halves, replacing the retaining bolts.

Further assembly of the washing machine is carried out in reverse order. First, the tank with the drum is put in place, and the motor, heater, pressure switch, and other internal components are connected to it. The pulley the belt is tightened drive. Finally, the Leran machine body is assembled.

Once assembly is complete, spin the washing machine drum by hand – it should rotate silently. Next, run a test cycle without laundry and observe the machine's operation. If the wash cycle runs normally, the repair is complete.

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment