How to change a bearing in a Vyatka-automatic washing machine?

On the one hand, replacing the drum bearing in a Vyatka automatic washing machine is much easier than in modern washing machines. All internal components are metal, secured with standard bolts. Older machines don't have intricate latches or tricky plastic fasteners that can easily break if pressed carelessly. However, repairing a Vyatka machine can present other challenges. Let's look at how to replace the bearing and explain the specific issues involved.

On the one hand, replacing the drum bearing in a Vyatka automatic washing machine is much easier than in modern washing machines. All internal components are metal, secured with standard bolts. Older machines don't have intricate latches or tricky plastic fasteners that can easily break if pressed carelessly. However, repairing a Vyatka machine can present other challenges. Let's look at how to replace the bearing and explain the specific issues involved.

Where can I get new bearings and seals?

The main difficulty in repairing old washing machines is finding replacement components. The first Vyatka-avtomat machines were manufactured back in 1981. Despite this long period of time, the units have been well-preserved and continue to function properly to this day.

Since Vyatka-automatic machines stopped being assembled in 2005, it is difficult to obtain spare parts suitable for this model today.

You'll have to look for replacement parts from more modern washing machines. To repair the bearing assembly, you'll need to find and purchase:

- Inner bearing. Ring dimensions: 30x62x16 mm;

- outer bearing, 25x50x15 mm;

- sealing rubber (oil seal), 38x62x10 mm.

There will be no problems with purchasing bearings. “Rings” of these sizes can be found in specialized stores or ordered online. They are quite common, as they are suitable for modern automatic machines Indesit, Ariston and others.

The seal will be more complicated. It's practically impossible to find a seal exactly the same size as the one on the Vyatka-Avtomat on the Russian market. You can try your luck at repair shops that specialize in disassembling and repairing appliances; you might just happen to find an old washing machine being sold for parts.

But there is a solution: you can find a 38x62x10 mm oil seal on AliExpress. It will cost around $3–$5, depending on the supplier. The only downside is the long delivery time. You'll have to wait a while to get your Vyatka-automatic washing machine repaired after years of faithful service.

How to disassemble a machine?

So, it was decided to repair the washing machine with our own hands. The work is simplified by the fact that to replace the bearings on the Vyatka machine there is no need to remove the front wall of the housing. It will be enough to remove the top panel and the rear technical hatch.

Before disassembling the washing machine, be sure to de-energize it and turn off the water supply tap.

The case can be disassembled using a screwdriver. First, remove a couple of screws securing the top panel. Once the fasteners are removed, you can gently slide the "cover" back—it will then easily come off. The rear panel is removed in a similar manner, after unscrewing the screws located around the perimeter of the service hatch. The rest of the procedure is as follows:

- remove the powder receptacle;

- loosen the clamps on the dispenser pipes, disconnect the hoses and remove the “hopper”;

- unscrew the bolts holding the cast iron counterweights, remove the weights from the housing;

- remove the drive belt from the pulley;

- remove the screws holding the motor;

- disconnect the wiring from the engine and remove the element from the housing;

- disconnect the wires from the heating element and the drain pump;

- disconnect the drain pipe from the tank;

- remove the lower counterweights;

- remove the outer clamp securing the hatch cuff;

- tuck the sealing rubber inside the drum;

- Unscrew the damper fasteners (the shock absorbers that hold the tank in the housing). It's easier to do this from behind the machine;

- disconnect the water level sensor tube;

- remove the upper springs that secure the tank;

- remove the tank-drum assembly from the housing.

The unit must be placed on a hard, level surface. Now all that's left to do is disassemble the tank, remove the damaged bearings, and install the new components. Let's figure out how to do this yourself.

We disassemble the tank and change the bearings.

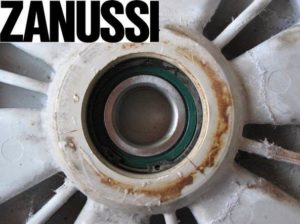

To change the bearings, you will need a screwdriver or drill, a small hammer, and a drift (which can be replaced with a regular metal rod). The tank of Vyatka-automatic machines is made of stainless steel and is collapsible. Simply unscrew the bolts around the tank to gain access to the drum. To remove the drum from the tank, you'll need to unscrew the crosspiece and carefully knock out the shaft. Let's look at the step-by-step procedure for replacing the bearings and seal:

- Use a thin screwdriver to pry up the oil seal and remove the rubber seal;

- Place the drift into the center of the outer bearing;

- tap the "ring" by moving the punch in a circle and hitting it with a hammer;

- Knock out the inner bearing in the same way.

This is how old bearings are removed. Before installing new components, clean the bearing surface of any dirt or metal shavings. Also, be sure to treat the bearing recess, the bearing rings, and the seal with a special lubricant—this will protect the unit from moisture and temperature fluctuations.

The shaft should also be cleaned. This can be done first with fine-grain sandpaper and then with GOI paste. To install the bearings, place them one by one into their respective recesses and carefully press them in with a drift and hammer. Tapping should only be done on the inner race of the ring, otherwise damage may occur.

Next, you need to replace the crosspiece, connect the tank halves, and begin reassembling the Vyatka-automatic. This is done in reverse order. The main tank is secured to the housing with dampers and springs, the pressure switch hose and drain pipe are connected, and the lower counterweights are installed. The seal, heating element, motor, drive belt, and other components are secured. Once assembly is complete, all that remains is to connect your "home helper" to the utility lines and run a test wash. If the machine does not hum and the drum rotates normally, the replacement has been completed correctly.

Interesting:

2 reader comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

What size bearings are these? For a truck?

There's no need to disassemble the entire machine. Only the universal joint needs to be removed. The bearings are pressed in through the outer ring.