How to change bearings on a tumble dryer

Experts note that dryer bearings are the most vulnerable component of the unit. Located directly beneath the drum, the motor is exposed to damp lint, which can penetrate through the gap and accumulate on and around the element housing. This leads to water ingress and corrosion, which ultimately leads to failure. In today's article, we'll discuss how to replace bearings on a dryer and what's important to consider when attempting this task yourself.

Experts note that dryer bearings are the most vulnerable component of the unit. Located directly beneath the drum, the motor is exposed to damp lint, which can penetrate through the gap and accumulate on and around the element housing. This leads to water ingress and corrosion, which ultimately leads to failure. In today's article, we'll discuss how to replace bearings on a dryer and what's important to consider when attempting this task yourself.

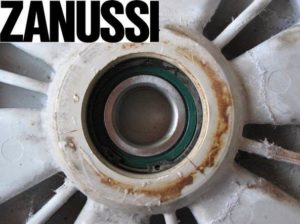

We remove the old bearings and install new ones.

The bearing is responsible for the smooth rotation of the washing machine's drum. However, over time, it can wear out and fail, so replacing it is key to restoring the appliance's normal operation. You can easily do this yourself. Below, we provide detailed instructions on how to perform this procedure correctly.

However, before you begin the repair, you'll need to complete a few preparatory steps. Be sure to have all the tools you'll need for the replacement part ready, and don't forget to unplug the unit and move it away from the wall so nothing can obstruct your access. Check the condition of the bearing that needs replacing.

The new part must have the same characteristics and dimensions as the old one!

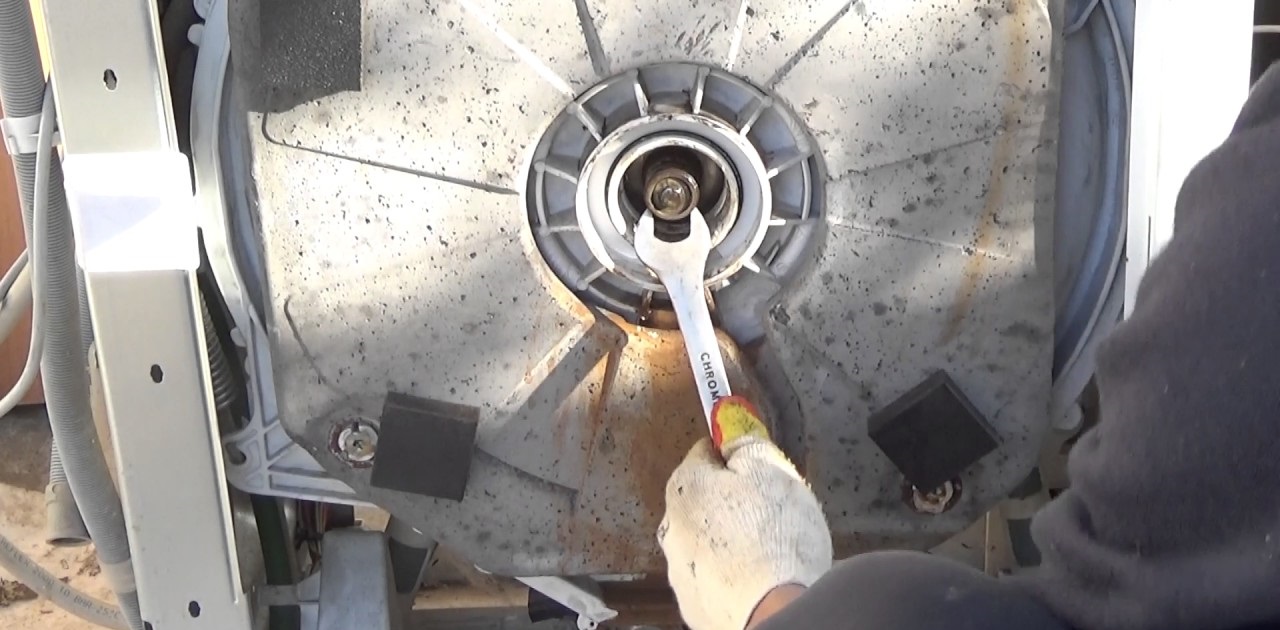

Make sure the bearing you purchased is compatible with your dryer before installing it. Using a wrench or screwdriver, you'll need to remove the back panel of the dryer. This will expose the bearing. It's typically located in the center of the dryer and attached to the drum shaft. Here's how to install it:

- remove the bearing;

- apply a little grease to the shaft and install the new element;

- make sure it fits tightly;

- secure the protective cover and replace the back panel of the dryer;

- tighten all the screws.

After all these steps, plug the device in and test its operation. If the element replacement was successful, the vibration and noise will disappear, and the device will operate smoothly. To keep your bearings in good condition for as long as possible, always clean the filters and vents. Debris in them will cause the device to overheat and wear out.

Don't forget to check the drum's load level. Overloading it can cause uneven weight distribution and increase stress on the bearings. Also, make sure it's balanced. If the drum rotates unevenly, this indicates a bearing problem.

Avoid overheating your machine: regularly check the temperature settings to prevent excessive heat buildup and wear on parts. Don't forget to perform preventative maintenance on your machine. If you notice any strange sounds or vibrations, contact specialists for diagnosis and repair. Following these simple recommendations will help prevent bearing failure in your dryer and extend its lifespan. Remember, regular maintenance and proper care are key to the longevity and efficient operation of your appliance.

After the bearings, the belt is changed.

Often, the drive belt needs to be replaced along with the bearings. This happens because a faulty drive belt causes the engine to malfunction, which in turn stretches the drive belt and creates problems with its operation. Let's figure out how to replace it correctly.

First, you'll need to unplug the dryer. Then, remove the damaged belt. To do this, follow these steps:

- Move the device away from the wall to allow you to approach it from any side;

- remove the lint filter from the machine;

- remove the side panels of the case;

- remove the top panel and the back wall.

After partially disassembling the housing, you'll reach the drive belt. In some cases, it may be worn out and lying underneath. You'll need to lift it out and dispose of it. If the element is still attached to the drum, you simply need to remove it.

This will complete the removal process and allow you to install the new belt. It's best to order the parts before starting the repair—this will allow you to use the model and serial number of your device. If you're concerned about making a mistake, remove the old belt, check its markings, and purchase a new one with the same specifications.

In most cases, finding spare parts for dryers is easy. If necessary, you can always use a car belt as a substitute. It's important that the belt diameter matches. If the part is too long, it will need to be carefully trimmed to ensure a secure connection.

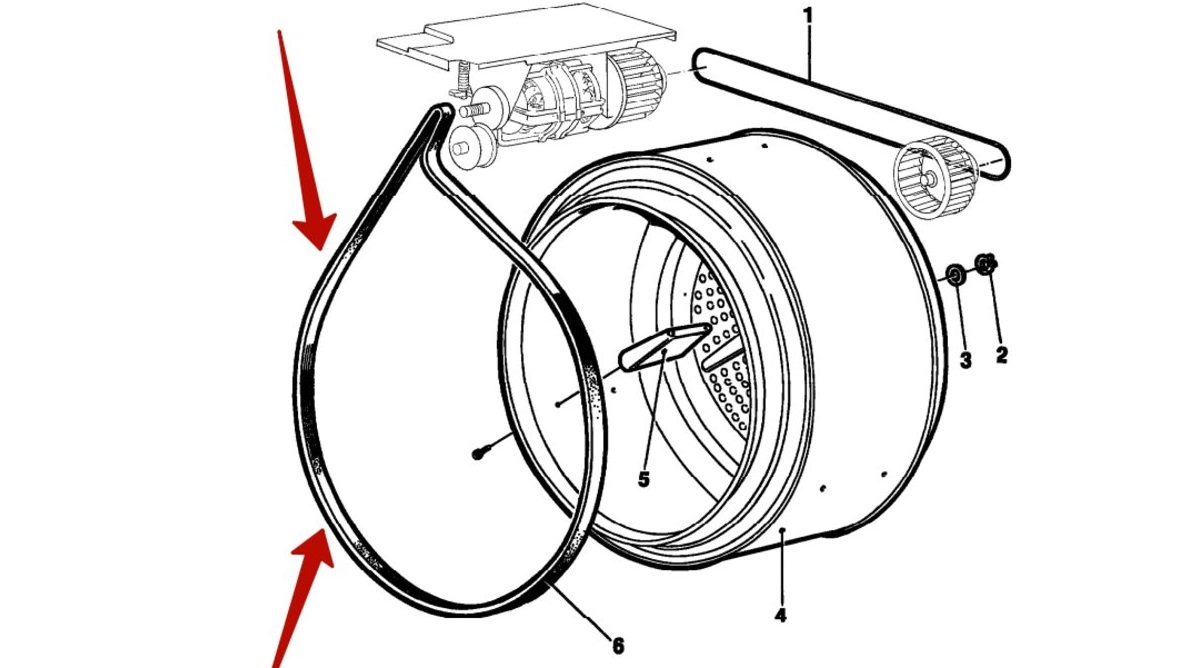

To install a new belt, wrap it around the drum. Then check how tightly it fits into the groove. After that, you'll need to:

- wrap the element through the tension pulley (it is located directly above the engine “wheel”);

- Turn the drum manually and make sure the belt is tightly seated;

- return the top panel of the case to its place;

- secure all clamps and reinstall the side panels of the housing, fastening them securely.

Then carefully slide the dryer back into place and plug it in. To ensure proper installation, run a test cycle with no items loaded. If the drum rotates smoothly and quietly, you've completed the task successfully.

To avoid future problems with your drive belt, follow a few simple rules and take care of your dryer. Clean the filter regularly to prevent dust and debris from accumulating and damaging the part. Inspect the belt for cracks, wear, or other damage. If you notice any issues, replace it immediately. Avoid overloading the dryer, as this can also affect the drive belt.

Additionally, always ensure that the part is installed correctly and in its proper place. If you have any doubts or problems, don't hesitate to seek professional help. Remember: regular maintenance and care of your equipment will help you avoid serious problems and save you both time and money.

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment