How to replace bearings on a Siemens washing machine

Replacing bearings in a washing machine is a rather labor-intensive task. A noticeable warning sign of bearing failure is an unpleasant noise, creaking, and banging sound emanating from the washing machine. These specific sounds will only intensify over time, and if not replaced, the machine will eventually rumble during the wash cycle and eventually stop working altogether. Therefore, if you notice any alarming symptoms, it's best to immediately have the washing machine diagnosed and replace the faulty part yourself.

Replacing bearings in a washing machine is a rather labor-intensive task. A noticeable warning sign of bearing failure is an unpleasant noise, creaking, and banging sound emanating from the washing machine. These specific sounds will only intensify over time, and if not replaced, the machine will eventually rumble during the wash cycle and eventually stop working altogether. Therefore, if you notice any alarming symptoms, it's best to immediately have the washing machine diagnosed and replace the faulty part yourself.

Let's gather everything we need

The scope of work is quite extensive: the unit will need to be disassembled almost completely. This will undoubtedly require auxiliary tools. To replace bearings on a Siemens washing machine, you'll need the following:

- Phillips and slotted screwdrivers;

- keys of various diameters;

- reversible screwdriver with a set of bits;

- pliers;

- a sealant characterized by excellent water resistance;

- punch;

- hammer with rubber tip;

- puller;

- several bolts and nuts;

- an ordinary small hammer.

In addition to a working tool kit, you should consider purchasing new parts. Seals and bearings can be purchased at specialty stores. When purchasing, you must provide the full model name of the washing machine or specify the factory part number, which can be found on the faulty components.

While disassembling the washing machine yourself, you may notice that the old bearings are heavily stuck to the surface and even partially destroyed. To make removing them easier, purchase WD-40, a multi-purpose aerosol lubricant.

The tanks of most Siemens machines are non-detachable and will need to be cut apart. A grinder will be useful for this.

We are approaching the tank

When attempting DIY repairs, keep in mind that you'll need to remove the drum and tub from the machine's housing. To do this, you'll first need to remove the housing walls and any components that might interfere with removing the tub. It's best to have a camera handy to document the process; this will make reassembling the unit easier. We'll provide you with a clear and concise procedure for replacing bearings in a washing machine.

- Remove the top cover of the machine by unscrewing the screws holding it in place. Set the cover aside.

- Remove the dispenser from the unit – a tray designed for loading detergents.

- Unscrew the bolts securing the control panel without disconnecting the connectors and carefully hang the element to the side.

- Using a screwdriver, remove the metal clamp holding the hatch cuff and tuck the sealing rubber inside the drum.

- Remove all counterweights and the fill valve from the machine housing, disconnect the filler pipe, and disconnect the wiring leading to the components. This will prevent damage to components during tank removal.

- Remove the false panel located at the bottom of the washing machine.

- Remove the front panel of the washing machine. This can be done by unscrewing all fasteners. At this stage, you should carefully unscrew the hatch locking device or simply remove the contacts from it.

- Unfasten the pressure switch and the hose leading to it.

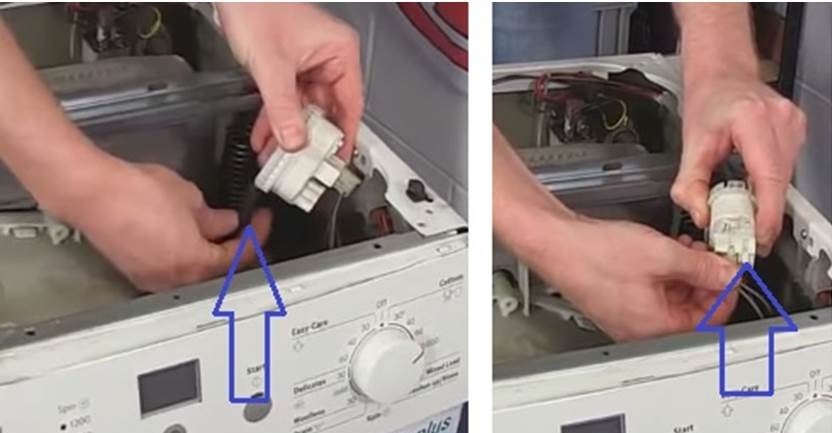

- Disconnect the contacts (power wires of gray, brown and black colors) and the ground (yellow or green wire) from the washing machine motor.

- Disconnect the sensor and heating element wires.

After completing the above steps, you will have free access to the tank. Carefully remove the element from the housing and place it on the floor. Note that the machine's motor is still attached to the tank. Remove the drive belt, unscrew the two bolts holding the motor, and set the motor aside. Disconnect the flywheel. You can proceed to the next step—disassembling the tank and installing new bearings.

Disassembling the tank and repairing the bearings

As mentioned above, the tanks of most automatic washing machine models are non-detachable, so to gain access to the bearings, you will have to cut or break off the fasteners connecting the two halves of the tank.

The problem may be with the internal fasteners that hold the hook. These can be either knocked off with a hammer or cut off. Otherwise, disassembling the cistern will be impossible.

Once the tank body is open, you can begin replacing the components. First, you need to remove the old oil seal. To remove bearings from the caliper, it is best to use a puller. If you see that the parts are stuck to the surface, treat them with WD-40 lubricant; this will make the process of removing the bearings much easier.

If you don't have a puller handy, you can use a special drift and a regular hammer. Using the hammer, tap out the outer and inner bearings.

The faulty components have been removed, and now all that's left is to install the new ones. First, install the outer bearing, driving it in carefully using a flat punch and a hammer.

The inner bearing is installed in a similar manner. Next, install the new seal. It's best to use the original rubber seal.

When installing a new oil seal, it is necessary to treat the part with a special lubricant.

The grease completely fills the seal lip, and the drum shaft is also treated at the point of contact with the seal. Lubricant is necessary to prevent moisture from getting onto the bearings, thanks to which the service life of the system components is significantly increased.

The next step is installing the drum into the tub. After that, install the flywheel and secure it. You can now reassemble the tub. Join the two halves of the part together and seal the joint with a waterproof sealant. Then, tighten all the previously removed bolts. After attaching the drive belt to the pulley and securing the washing machine motor, you can reinstall the tub into the machine body.

Reassembly of the Siemens machine is performed in reverse order. The photographs will help you accurately reconnect all the wires, contacts, and hoses disconnected during repair work.

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment