How to Replace Bearings in a Top-Loading Washing Machine

Replacing bearings in a vertical lift is a rather labor-intensive procedure. Knowing that all the removed components will need to be replaced after installing the new bearings may make you doubt your abilities, but don't worry too much. You can do the replacement yourself, without the help of a professional; just carefully read the instructions.

Replacing bearings in a vertical lift is a rather labor-intensive procedure. Knowing that all the removed components will need to be replaced after installing the new bearings may make you doubt your abilities, but don't worry too much. You can do the replacement yourself, without the help of a professional; just carefully read the instructions.

Let's get some tools

So, you've finally decided to repair your washing machine yourself. Before you begin disassembling your automatic machine, make sure you have all the tools necessary to carry out the work. During the repair process you will need:

- two types of screwdrivers: Phillips and flat;

- screwdriver;

- open-end wrenches of various sizes;

- set of hex keys;

- metal rod.

In addition to tools, you'll need new parts to replace the faulty ones. To do this, find out the full name of your top-loading washing machine. You can find the brand name in the manual or on the label on the machine.

In addition to tools, you'll need new parts to replace the faulty ones. To do this, find out the full name of your top-loading washing machine. You can find the brand name in the manual or on the label on the machine.

The full model name will make it easier for you to find new components.

You can purchase bearings either at specialized retailers or by ordering online. To replace faulty parts, you'll need to purchase:

- A set of bearings for a specific washing machine model. For top-loading machines, prefabricated bearing kits are available;

- Oil seals. Selected in accordance with the automatic machine being repaired;

- special lubricant for seals and bearings;

- universal aerosol lubricant WD-40 (or another liquid with a similar operating principle).

Once all the tools and components are ready, you can begin preparing the washing machine. To do this, turn off the power and disconnect the water inlet and outlet hoses. It's best to have a smartphone with a good camera and a notepad and pen handy. When disassembling equipment, it's best to photograph each step, take pictures of how parts, wires, and contacts should be positioned, and, if necessary, make notes in a notebook. This precaution will help you reassemble your top-loading washing machine correctly and quickly.

Preparing and disassembling the washing machine

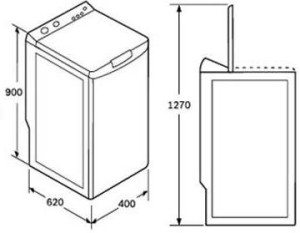

Once the machine is disconnected from the power supply and utilities, you can begin disassembling the unit. To do this, you'll need to ensure easy access to the machine, so it's best to move it to a spacious room or garage. The next steps are as follows:

- First, you need to remove the right side panel of the housing. To do this, you'll need to unscrew three screws located on the back. Most vertical models have the pulley located on the right side;

- Carefully pull the drive belt off the pulley;

- Using a screwdriver, unscrew the bolt holding the washing machine drum pulley.

The first part of the job is the simplest and usually doesn't cause any difficulties. Once the drum pulley is removed, set it aside. Now you can move on to the main stage of the repair process.

We change bearings

Once the pulley is removed, you need to disconnect the drum grounding connection located near the support. Using a Phillips-head screwdriver, remove the bolts holding the part in place.

Now it's time to remove the old caliper. To do this, you'll need a pair of screwdrivers and a long metal rod to act as a lever. Insert the screwdrivers into the holes in the caliper from opposite sides, and place the rod between them.

Which way should I unscrew the support? Carefully examine the support; it should be marked with the direction of movement and labeled "Open." By pressing firmly on the lever and turning the screwdrivers several times, you will remove the element from the washing machine body.

Most top-loading washing machine models come with ready-made bearing supports, including both the seal and bearings. Simply slide the new support onto the shaft. The part usually comes with a bushing containing grease, which is used to treat the surface of the element before inserting it into the washing machine. The lubricant is applied in a thick layer to the oil seal and the drum shaft in the area of its contact with the oil seal.

It is essential to treat the parts with lubricant; this will ensure good moisture resistance of the connection, reduce the susceptibility of the elements to wear, and guarantee a long service life.

If the caliper doesn't come with a lubricant, you can use any grease designed for washing machine bearings and seals. After the surfaces are cleaned, carefully screw the caliper back into the housing. To do this, take two screwdrivers and a rod again and rotate the part in the opposite direction. The support must be fully inserted and fit securely into its seat.

We put the equipment back together

The main work is done, all that remains is to reassemble the vertical machine. To restore the machine to its original appearance, follow these steps:

- put the drum pulley back in place;

- screw in the grounding that was disconnected at the beginning of the work;

- install the fastening nut that holds the pulley in place and tighten it well;

- tighten the drive belt;

- attach the side cover to the body.

If you see the main signs that a drum bearing has failed, don't rush to call a repairman. Once you understand the work involved, you can replace the parts yourself.

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment