How to change the belt on an Ardo washing machine?

The drive belt found in automatic machines with a commutator motor tends to stretch. After several years of use, the elastic can begin to slip. It's easy to notice when the belt slips—the machine simply won't start washing because the drum can't spin. You can replace the drive belt on your Ardo washing machine yourself, without calling in a professional. Let's figure out how to repair your washing machine in this situation.

The drive belt found in automatic machines with a commutator motor tends to stretch. After several years of use, the elastic can begin to slip. It's easy to notice when the belt slips—the machine simply won't start washing because the drum can't spin. You can replace the drive belt on your Ardo washing machine yourself, without calling in a professional. Let's figure out how to repair your washing machine in this situation.

How does a belt defect manifest itself?

You can't tell if the drive belt has come off just by inspecting the machine—it's hidden behind the back panel. Therefore, to confirm the problem, you'll need to use a screwdriver. Modern Ardo washing machines can notify the user of the problem. Thanks to the built-in self-diagnostic system, the machine determines the cause of the failure and displays the corresponding error on the display. Once you see a fault code on the display, all you have to do is get out the Ardo manual and read the code. Units without a display will indicate the problem by flashing LEDs on the dashboard.

Sometimes self-diagnostic sensors don't detect that the belt has slipped off the shaft, so the error code doesn't appear. The user can often detect a malfunction based on unusual behavior of the washing machine. You can suspect problems with the drive mechanism if:

- the machine started the cycle, water poured into the tank, the electric motor started working properly, but the drum was still “standing”, not moving;

- The washing machine's motor makes noise, then immediately dies down and stops working. The motor's state fluctuates at regular intervals;

- the wash starts, the engine operates as usual, but the washing machine “freezes” and does not respond to user requests;

- The drum rotates freely by hand, although the motor cannot set the “centrifuge” in motion.

An automatic washing machine with a slipped drive belt will not be able to wash clothes; it is necessary to return the elastic to the pulley as soon as possible.

If you notice any of these symptoms, you should turn off the machine as soon as possible. Running the machine for a long time with a slipped belt can cause the motor to overheat and fail. After disconnecting the power, check to see if the drive belt is in place. This will require partially disassembling the machine. Let's look at how to restore the machine's functionality yourself.

Belt replacement procedure

If the belt does come loose, don't call a professional right away. You can tighten the belt yourself, just follow the instructions. The job isn't entirely straightforward: the belt is quite tight, and fitting it onto the pulley requires patience and skill. However, if you follow the instructions, even a novice can handle the repair.

If the belt has slipped for the first time, you don’t need to change it; simply install the same rubber band in its original place.

When the drive belt slips periodically, a new part needs to be installed. To assess the condition of the rubber belt, follow these steps:

- unplug the machine's power cord from the socket;

- disconnect the washing machine from the house network, detach the drain corrugated pipe and the inlet hose from the body;

- move the device away from the wall so that you have free access to the back;

- remove the “top” of the case by unscrewing a couple of screws holding it in place;

- unscrew the bolts around the perimeter of the rear wall and move it to the side;

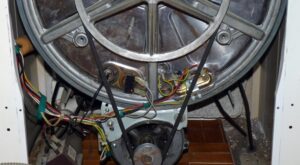

- Find the belt. Its position is the same on all Ardo collector models. The rubber band runs between the drum wheel and the small pulley of the electric motor. If the belt comes off, it will be lying under the washing machine;

- check the condition of the rubber band.

Carefully inspect the part and look for the markings on it. The first four digits indicate the factory diameter of the strap in mm. Measure the circumference of the elastic and compare it to the original size. A belt that has stretched more than 2 centimeters is no longer suitable for further use and will need to be replaced. When selecting a new drive belt, it's important to consider both its markings and the Ardo washing machine model. Once you've purchased a replacement belt, you can begin installation. The procedure is as follows:

- Place the belt on the electric motor pulley;

- Pull the rubber onto the drum "wheel" by slightly turning the pulley to the left.

If possible, it's best to work with two people, using four hands. This will make tensioning the belt easier and faster. Keep in mind that the factory rubber band can be very tight, and getting it into place can take a fair amount of effort. You can tell if the belt is tight by turning the pulley. If the drum "wheel" rotates with tension, the job has been done correctly. After checking the installation, reassemble the machine (securing the rear and top panels), connect the appliance to the house utilities, move the appliance to the wall, and run an empty wash cycle.

The belt doesn't hold

Sometimes, even a new rubber seal comes off after just a couple of months of use. This is a warning sign that could indicate certain problems with the machine.

If the belt falls off the pulley more than once every 3 months, it is necessary to perform a comprehensive diagnosis of the Ardo machine.

Constantly falling drive belt can be caused by:

- Wear and tear of the element. The elastic tends to stretch. If its surface has cracks or defects, or if its length has increased by more than 2 cm from the factory specifications, the part should be replaced. If the belt wears out too quickly, within just a few months, it's likely due to improper operation of the washing machine, for example, by exceeding the permissible load weight.

- Drum play. In this situation, replacing the belt won't help; it will continue to come off. The problem can be solved by tightening the main pulley screw. In severe cases, the entire drum "wheel" will have to be replaced;

- Poor motor mounting. The motor of Ardo washing machines is securely fastened at the factory, but under intensive use, the element can become loose. To fix this, simply tighten the motor mounting bolts.

- Pulley deformation. This situation can easily arise after unqualified equipment repair. Sometimes technicians fix one component while simultaneously breaking another. If a "wheel" is bent, it can be straightened. It's better, of course, to install a new, straight component.

- A defective spider. This damage could be a manufacturing defect or a new problem caused by excessive vibration during operation. The spider must be replaced. Otherwise, the situation could lead to drum imbalance, which would be a more expensive and labor-intensive repair.

- Damage to the bearing assembly. Broken bearings cause the equipment to become unbalanced, which can cause the drive belt to slip. It's important to replace the metal rings and, at the same time, the seal.

Sometimes the drive belt falls off due to incorrect positioning on the pulley - when the rubber is not inserted into the special grooves.

In some cases, the reason for the belt to regularly come off is the installation of components that are not suitable for the given washing machine. It is necessary to select a drive belt suitable for a specific model of automatic machine. Ardo. If the rubber belt has fallen off for the first time after several years of use, you can simply buy a new belt and install it yourself. If the belts keep falling off, even with new ones, you'll need to take a more serious approach and perform a full diagnosis of the components that ensure the drive mechanism's operation.

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment