How to change the belt on a Vestel washing machine?

All automatic washing machines with a commutator motor are equipped with a drive belt. The elastic tends to stretch, especially if the user violates basic operating rules: failing to comply with the maximum load weight, not leveling the washing machine, etc. Replacing the drive belt on a Vestel washing machine is possible yourself. This repair is considered quite simple. We'll explain the process and how to properly tighten the elastic belt onto the drum pulley.

All automatic washing machines with a commutator motor are equipped with a drive belt. The elastic tends to stretch, especially if the user violates basic operating rules: failing to comply with the maximum load weight, not leveling the washing machine, etc. Replacing the drive belt on a Vestel washing machine is possible yourself. This repair is considered quite simple. We'll explain the process and how to properly tighten the elastic belt onto the drum pulley.

Is this really a belt?

It's not immediately obvious that a belt has come loose. You can confirm this by removing the back panel of your Vestel washing machine. Modern machines can automatically indicate a problem by displaying a corresponding error code or flashing indicators. The user simply needs to consult the manual and decipher the error message.

Sometimes, the self-diagnostic system simply doesn't notice that the rubber has slipped off the pulley. In this situation, no code will appear on the display. However, it's not hard to spot problems with the drive belt. The following unusual behavior patterns may be observed in the washing machine:

- The wash cycle starts, water begins to fill the tank, the motor is activated, but the drum does not move, frozen in place;

- The engine runs, hums, stalls after a few seconds, and then starts making noise again. The engine's state changes occur at approximately equal intervals;

- the cycle begins, the electric motor operates normally, but the washing machine “freezes” and stops responding to user commands;

- The electric motor cannot set the drum in motion, while the "centrifuge" spins smoothly when operated manually.

Washing with a slipped drive belt is impossible; it is necessary to return the rubber band to the pulley as quickly as possible.

If you notice even one of the described “symptoms,” you need to quickly turn off the equipment using the button and pull the power cord out of the socket. If the washing machine Vestel will operate with a slipped drive belt, which may overheat and cause the electric motor to fail. Therefore, you should immediately begin diagnosing the equipment. To check if the belt is in place, you'll need to partially disassemble the case, specifically the top and back panels. We'll explain how to perform a DIY diagnostic and restore your Vestel washing machine to life.

Instructions for replacing the part

You can change the belt on a Vestel automatic machine yourself. If this happens, there's no need to call a technician—no special knowledge or tools are required. To tighten the belt, it's important to follow the instructions and the procedure described. In reality, the only difficulty you might encounter is tensioning it. The new belt is quite tight, and getting it onto the pulley can be a bit of a struggle. However, a few tips will help you overcome this minor issue.

If the belt has come off for the first time and it is not damaged or stretched, you can try to put the rubber band back in place.

When the belt falls off for the third time, you need to buy and tighten a new part. To determine whether the elastic is still in place and in what condition it's in, follow these steps:

- de-energize the equipment by unplugging the power cord from the outlet;

- turn off the valve responsible for the water supply;

- move the “home assistant” away from the wall to gain access to the back of the case;

- disconnect the inlet hose and drain sleeve;

- unscrew the bolts holding the “cover”, remove the top panel and put it aside;

- unscrew the screws around the perimeter of the rear wall;

- remove the back panel.

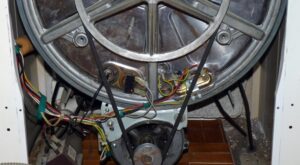

Now you can check to see if the elastic is still in place. If it has slipped, you need to pick it up from the floor. Next, measure the circumference and compare the measurement with the number on the label. When the drive belt is stretched more than 20 mm compared to the initial size, it must be replaced. When purchasing a replacement belt for your Vestel washing machine, use the model and serial number as a guide. The markings on the old belt can also help you find a replacement. To replace the belt:

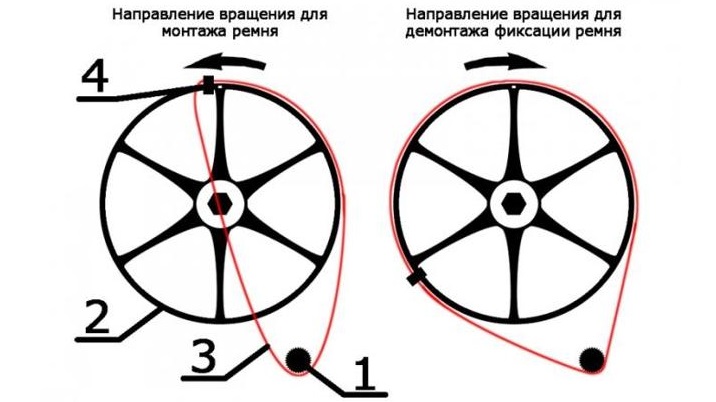

- put it on the shaft (of the electric motor);

- attach the rubber band to the drum pulley and pull it onto the “wheel”;

- hold the belt with one hand and turn the pulley to the left with the other;

- put the elastic band on completely.

Of course, it's much easier to install the drive belt with two people. However, if you don't have a helper, don't worry—you can tighten the belt yourself in just a few minutes. Once you're done, check that the belt is securely fastened to the pulley. The drum wheel should rotate with tension. Once you're sure the repair is complete, reassemble the machine, securing the back and top panels in place. Next, connect the inlet hose and drain hose, open the shutoff valve, and run a test wash. The machine should be empty. If the drum spins normally, the belt replacement has been completed correctly.

The belt often comes off

Some users may notice that the drive belt starts to come off quite frequently, every few months. If even replacing the old belt doesn't fix the problem, you'll need to dig deeper. This is a warning sign, indicating some malfunction in the equipment. Many factors can cause belt slippage.If you notice that the belt is falling off the pulley too often, be sure to conduct a comprehensive diagnosis of the automatic machine. Vestel. Periodic slipping of the drive belt may be caused by:

- Wear of the rubber belt. If the belt wears out too quickly, literally within 2-3 months, it's either made of low-quality materials or the user isn't following the basic operating instructions for the washing machine. For example, the rubber belt "suffers" when the maximum load weight is constantly exceeded;

- Play. If the drum is loose, no matter how many times you replace the rubber seal, it will eventually come loose. Usually, the fix is simple—just tighten the pulley retaining nut. A complete replacement of the drum "wheel" may be necessary;

- Incomplete motor locking. The machine vibrates during operation, which can cause the motor mounts to loosen. To resolve this, simply tighten the screws holding the electric motor to the housing;

- Changing the pulley shape. Sometimes a drum wheel is accidentally damaged during repairs to a "home helper." If the dent is small, you can try straightening the rim. It's best, of course, to purchase and install a new, straight pulley;

- Damage to the universal joint. This defect can be either factory-installed or acquired. Due to strong vibrations during machine operation, the drum-tub assembly components become unusable. In this situation, the universal joint must be replaced; continued use of the machine with this problem will lead to complete drum imbalance.

- Bearing assembly wear. Damaged bearings cause the housing to become misaligned, causing the drive belt to slip off the pulley. Damaged rings and the seal must be replaced immediately.

The reason for the drive belt constantly coming off may be its incorrect installation - the rubber must fit into the grooves of the pulley.

Additionally, a belt that's not suitable for a specific Vestel model can slip regularly. Therefore, it's crucial to purchase components designed specifically for your washing machine, paying attention to the part markings. For example, if the belt slips for the first time after several years of use, don't worry too much. Simply buy a new part and replace the belt yourself. If slipping occurs periodically, over short periods of time, a more thorough diagnosis of the machine's drive mechanism and other internal components is required.

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment