How to change brushes on a Beko washing machine

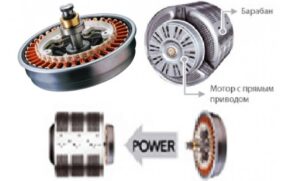

Budget Beko washing machines are equipped with brushed motors. The motor housing contains the stator, rotor, their windings, and a pair of brushes. The purpose of the brushes is to supply electricity to the rotor.

Budget Beko washing machines are equipped with brushed motors. The motor housing contains the stator, rotor, their windings, and a pair of brushes. The purpose of the brushes is to supply electricity to the rotor.

Graphite rods are subject to natural wear. After approximately five years of use, the brushes in your Beko washing machine may need replacing. This repair is considered simple and can be done yourself, without calling a professional. We'll show you how.

Are the brushes really broken?

If all washing machine operating instructions are followed, the need for brush replacement will not arise until 5 years after purchase. If the machine is used every 3-4 days, the replacement period will be 7-10 years. However, sometimes repairs are required after just 2-3 years if the machine is used daily, and with irregularities.

How do you know when it's time to replace your brushes? The following symptoms indicate worn carbon rods:

- a short-term malfunction of the washing machine during the cycle (given that the power supply is normal);

- the appearance of crackling and unusual noise when the drum rotates;

- deterioration in spin quality (due to the fact that the engine cannot spin the drum to the required speed);

- a burning smell when the washing machine is running;

- display of the corresponding error code on the washing machine display.

The error code E11 indicates wear of the electric brushes in the Beko washing machine motor.

Even one "symptom" is enough to prompt replacement of the brushes. And if there are multiple signs of malfunction, it's definitely not worth delaying repairs. Before buying replacement parts, it's best to disassemble the machine, remove the motor, and inspect the condition of the carbon brushes. This will help you determine if the problem is truly there.

Spare parts are purchased for a specific Beko washing machine model. The brushes of a commutator motor are always replaced in pairs. Even if only one graphite rod is worn out, it's important not to neglect this rule.

There's no need to worry about the upcoming repair. Replacing the wiper blades is quite simple. The process requires minimal tools, and the entire job takes no more than an hour. The main thing is to follow the instructions and observe safety precautions.

How to get new brushes

It's important to avoid mistakes when selecting new components for your washing machine. Therefore, it's recommended to remove damaged brushes and show them to the store clerk as a sample. This will prevent you from purchasing inappropriate parts.

Disassembling will reveal the exact brushes in your washing machine. It's best to buy genuine Beko washing machine parts. Cheap Chinese alternatives will fail faster, requiring replacement.

If you're unsure whether the components are compatible with your machine, consult with the seller. When ordering new brushes yourself online, search for parts based on the model and serial number of your Beko washing machine. Carbon rods are inexpensive—around $5–$6 per pair.

Preparing the car for engine removal

Before you begin dismantling the engine, you need to complete a few steps. First, gather the tools you'll need. These include Phillips and flat-head screwdrivers and an 8mm Torx key. A pencil or marker will also be helpful.

The next step is preparing the washing machine itself. Ensure free access to the machine from all sides. Here's what you need to do:

- de-energize the washing machine by unplugging the power cord from the outlet;

- close the shut-off valve responsible for the water supply;

- detach the drain and inlet hoses from the washing machine;

- remove the lower false panel behind which the drain filter is hidden;

- cover the floor around the machine with dry rags;

- Place a small container under the housing, in the area where the drain filter is located;

- unscrew the washing machine's debris filter by half a turn;

- wait until the water drains into the container;

- remove the filter completely;

- Clean the resulting drain hole from debris and dirt.

After completing these steps, you can move the washing machine away from walls and other furniture so that you have access to it from all sides. Next, you can begin removing the electric motor.

Removing old brushes and installing new ones

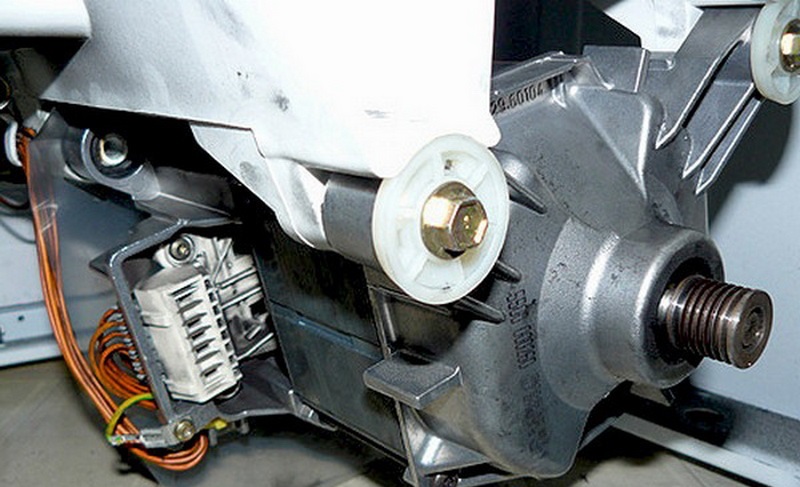

As mentioned earlier, the brushes are part of the commutator motor. Therefore, first, you need to remove the motor from the washing machine. It's located at the rear of the housing. Here's how to proceed:

- Unscrew the 2 bolts securing the top panel of the machine;

- remove the "top" of the case;

- Remove the screws securing the back panel of the machine, remove and put away the panel.

The motor is located under the drum of the automatic washing machine. Beko washing machines have a belt drive, so now you'll have to work on the mechanism:

- remove the drive belt from the drum pulley (to do this, you need to carefully pull the rubber band while turning the wheel);

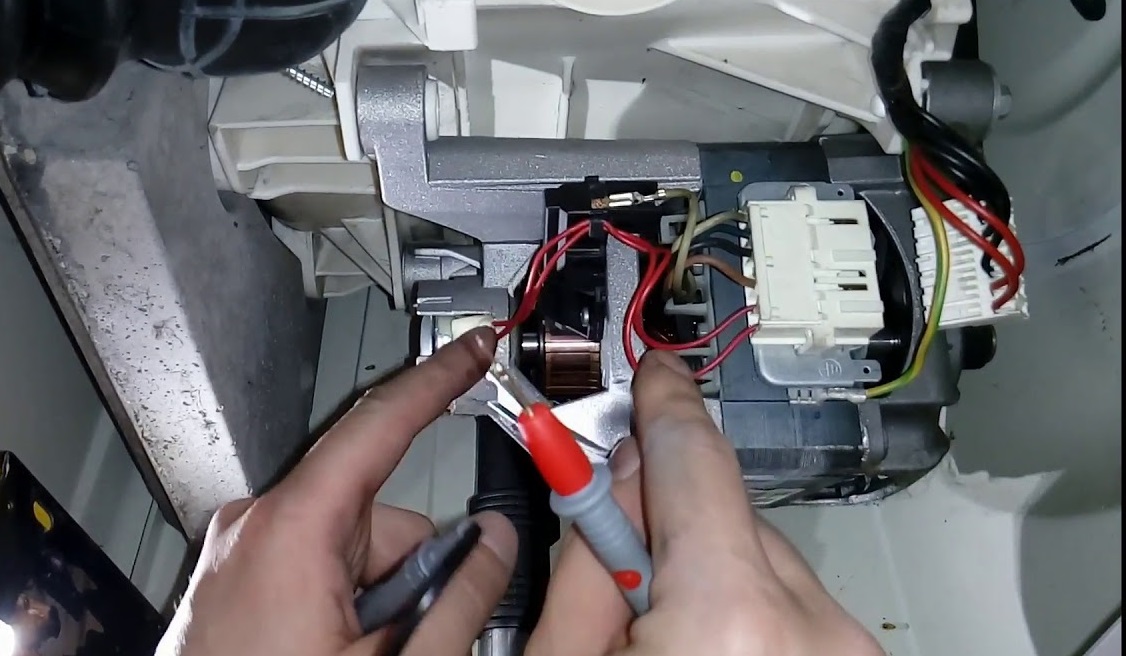

- Disconnect all wiring connected to the engine.

Before you reset the chips, it's best to take a photo of the wiring diagram for the motor—this will help you avoid making mistakes during reassembly.

Now you can begin removing the engine. The motor is secured to the washing machine housing with bolts, which can be removed with an 8mm Torx key. Once the fasteners are removed, grasp the manifold with both hands and, using a rocking motion, lift it out of its mounting. This part is quite heavy, so keep this in mind.

The brushes are located on the sides of the motor. Now you can begin inspecting them. The most common carbon rods found in the Beko washing machine commutator motor are those with the following interchangeable codes: 00215815, 371201201, 371201205, 371201202, 481281719408, and CAR029UN. The standard dimensions of the elements are 5 x 12.5 x 32 mm. However, it's best to double-check the information, as the components may vary between models.

Worn-out brushes will be noticeably worn. As mentioned, elements are replaced in pairs, even if one carbon rod retains its original appearance. How to install new carbon brushes:

- disconnect the cable;

- carefully move the contact down;

- carefully stretching the spring, pull out the brush;

- Unpack the new carbon element;

- place the tip into the socket;

- compress the spring and place it into the socket;

- close the electric brush with a contact;

- connect the cable.

The same steps are taken with the second brush. If you replace only one "carbon," the elements will wear out very quickly, and repairs will have to be repeated within a few months. Once this work is completed, you can begin reassembling the washing machine. Here's the procedure:

- return the motor to its mounting position;

- secure the engine with bolts;

- Using the photos as a guide, connect the wires to the electric motor;

- pull the drive belt back (first onto the large pulley, then onto the small pulley);

- put the back wall of the washing machine housing back in place and secure it with screws;

- put the top panel on and secure it with bolts;

- screw the drain filter back in;

- install the bottom false panel;

- Connect the drain and inlet hoses to the machine.

Now you need to run a test wash. The engine may make noise for several cycles after such a repair, and this is normal – the brushes need time to grind in.Observe the machine, see how it spins the drum, and whether there is a burning smell.

Ensure that the symptoms indicating a malfunction have disappeared. If there are no problems, consider the job complete. To prevent premature wear of the brushes, it is important to adhere to the manufacturer's maximum load capacity and avoid imbalance.

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment