How to replace a triac in a washing machine?

Replacing a triac in a washing machine is fairly simple; anyone with a soldering iron can handle it. The main difficulty is identifying which semiconductor on the board is damaged and selecting a component that is identical to the faulty one. These two problems are not easy for the average person to solve. Let's look at how to properly diagnose the problem and find the right components.

Replacing a triac in a washing machine is fairly simple; anyone with a soldering iron can handle it. The main difficulty is identifying which semiconductor on the board is damaged and selecting a component that is identical to the faulty one. These two problems are not easy for the average person to solve. Let's look at how to properly diagnose the problem and find the right components.

Let's make sure the element is faulty

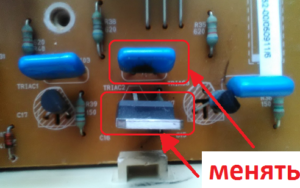

First of all, you will need to gain access to the washing machine control board. To diagnose semiconductor elements, you will need a special device – a multimeter. To partially disassemble the machine, you only need a screwdriver. The procedure is as follows:

- de-energize the washing machine;

- turn off the tap that supplies water;

- remove the top cover of the case by unscrewing 2 bolts;

- remove the powder container;

- Unscrew the bolts holding the control panel;

- Take a photo of the connection diagram of the instrument panel to the board to avoid making mistakes during subsequent assembly;

- reset the contacts and remove the dashboard.

To obtain more accurate results, it is recommended to desolder the triac before diagnosing it.

However, the method involving desoldering the semiconductors is more complicated and requires additional manipulation of the electronic components on the control board. Therefore, beginners prefer to test the triacs directly in place, without disconnecting them from the module.

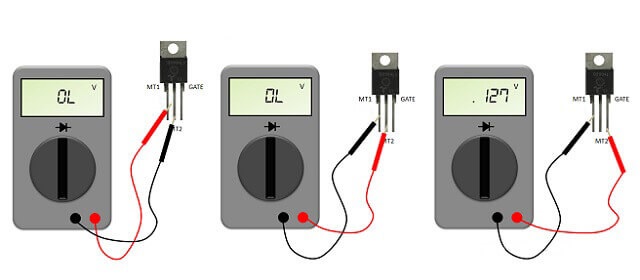

To test a semiconductor for breakdown, place the multimeter probes against the triac's power contacts (the left and middle legs). The tester's screen may display either 0 (indicating a faulty component) or 1 (meaning the part is fully functional). Some devices display the letters "OL" instead of "1," which also indicates sufficient resistance.

In the second stage of diagnostics, move one of the multimeter probes to the control terminal. The voltage drop should be between 100 and 200, with slight variations acceptable.

Next, check whether the semiconductor junction opens. To do this, hold the multimeter probes on the power terminals and quickly touch the control contact. The readings on the tester screen should change immediately. This correction indicates the triac is working properly.

If the tested semiconductor produces correct results at all diagnostic stages, the problem is not with that circuit element. Other triacs will need to be tested. If the fault is confirmed, the component must be replaced.

How to select a replacement part?

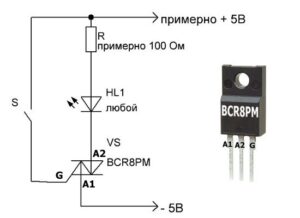

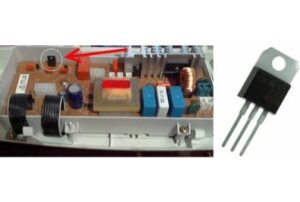

When deciding to replace a semiconductor, it is important to take a responsible approach to selecting components. When purchasing a new triac, you should pay attention to the element's insulation, its peak rating, and its opening current. But how can you find out the characteristics of a part removed from the washing machine control board?

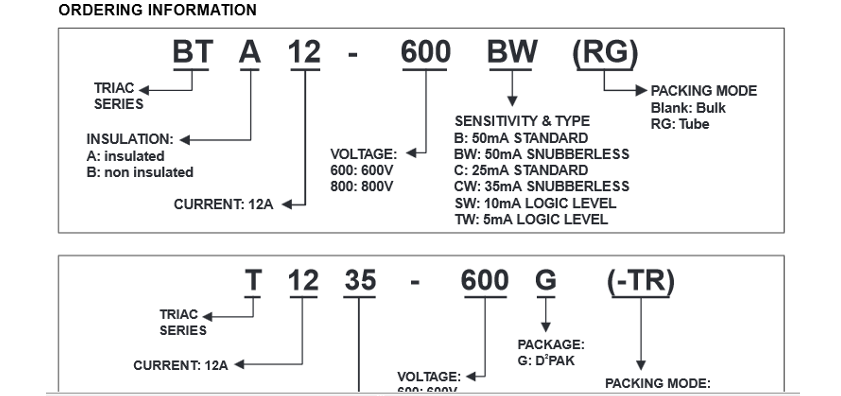

Look at the markings on the faulty triac – by deciphering the inscription, you can find out all the necessary information about the semiconductor element.

Therefore, the first thing to do after desoldering and diagnosing the triac is to copy its markings onto paper. For example, if the original semiconductor is marked BTB 15-700BAK, it contains the following information:

- BT – semiconductor element series;

- B – indicates that the triac body is not insulated (at the same time, the index “A” indicates that the semiconductor is isolated);

- 15 – peak current of the triac (in this example, 15 Amperes);

- 700 – peak voltage (in our case it is 700 Volts);

- VAK is a combination indicating the triac's opening current, which in this example is 50 mA. The CB designation indicates an opening current of 10 mA.

The last letters of the marking are significant. If the control board had a triac with a 50 mA firing current, and the purchased component is characterized by only 10 mA, the machine will not operate at full power, but only at 10-20% of its potential.

You cannot buy replacement thyristors with lower peak current and voltage – these parameters must match or exceed the original ones.

It's also worth paying attention to the index, which indicates whether the triac is insulated or not. For example, the semiconductor with the "B" characteristic discussed in the example could easily be replaced with an analog with the "A" index.

If your control board had an isolated triac, such as the BTA 15-700BAK, you should also buy a replacement semiconductor with the "A" index. Installing a new component without insulation could easily short out the control module. Therefore, it's best not to take any risks.

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment